Pleated air filters and non-pleated air filters are two common types of filters, and they have their own advantages and disadvantages in terms of filtration efficiency, service life, maintenance requirements, and applicable scenarios. The following is a detailed comparison of the characteristics of these two types of filters from various aspects:

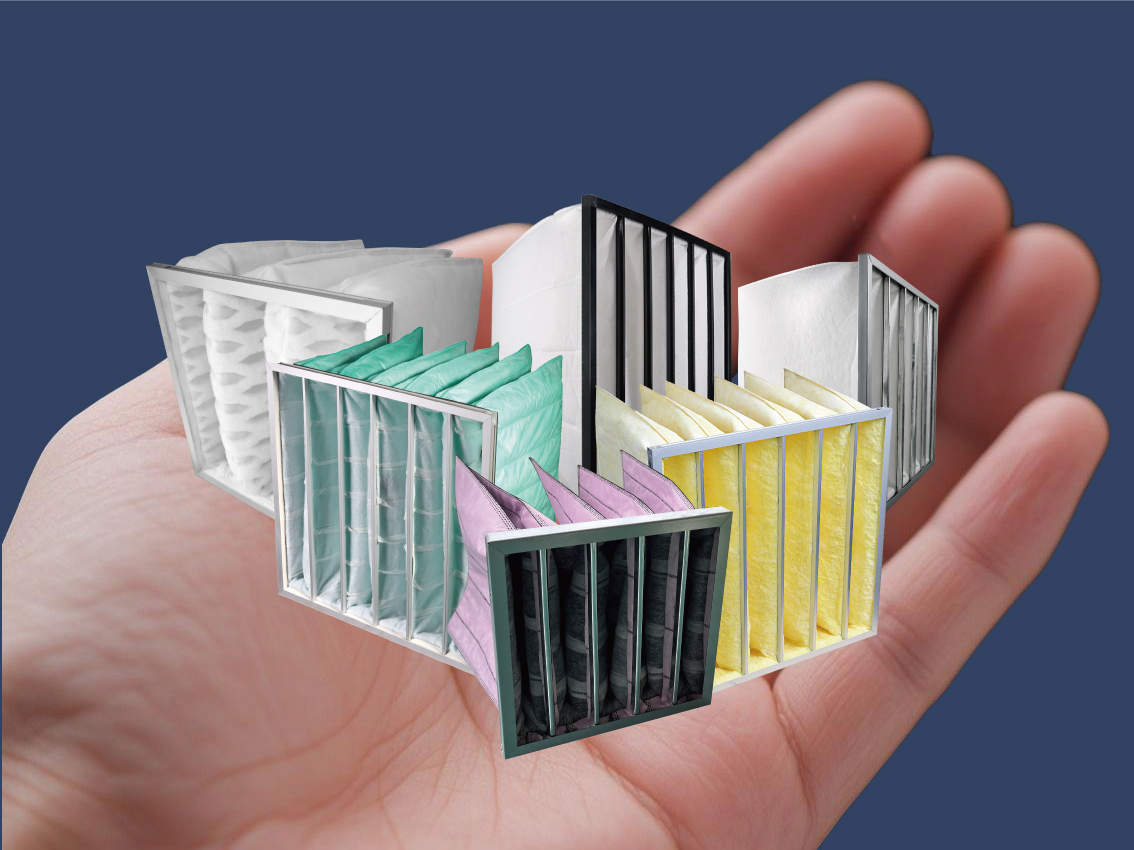

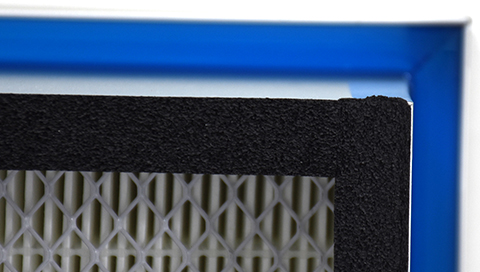

Pleated filters are widely used in pre-filtration and mid-range air filtration, with filtration efficiencies ranging from G4 to F9, which can meet the needs of air purification in different scenarios. In terms of filter element materials, we offer a wide range of options, including primary cotton, needle punched cotton, high

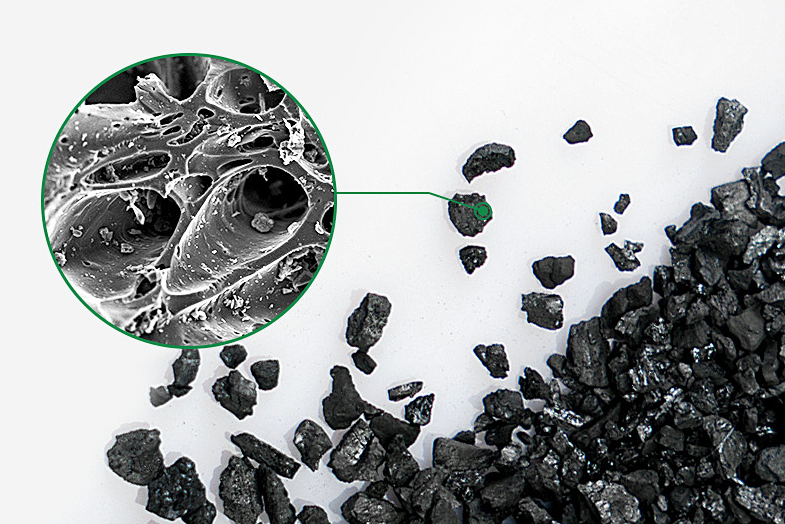

temperature cotton, bag roll material, folding material, activated carbon cotton, electrostatic cotton, etc., which can be flexibly matched according to the actual use environment.

In terms of production process, we adopt the mesh-covering technology, which firstly reinforces the filter material with mesh-covering and then makes precise folding treatment. The filter material after the coating process not only has a more stable structure but also can effectively prevent the filter material from falling off or breaking, which greatly improves the durability and service life of the filter.

In addition, we have also launched a unique product - the sub-frame detachable prefilter.

The biggest advantage of this product is that it supports disassembly and cleaning, users only need a few simple steps to disassemble the filter for deep cleaning, and after cleaning, it can be put back in the same way to continue to use, which is not only convenient and quick, but also can significantly reduce the cost of use.

A non-pleated air filter is a type of air filter that uses a flat or panel-style design instead of the traditional pleated (folded) structure. Unlike pleated filters, which increase surface area through accordion-like folds, non-pleated filters rely on a single-layer or multi-layer flat media to capture particles.

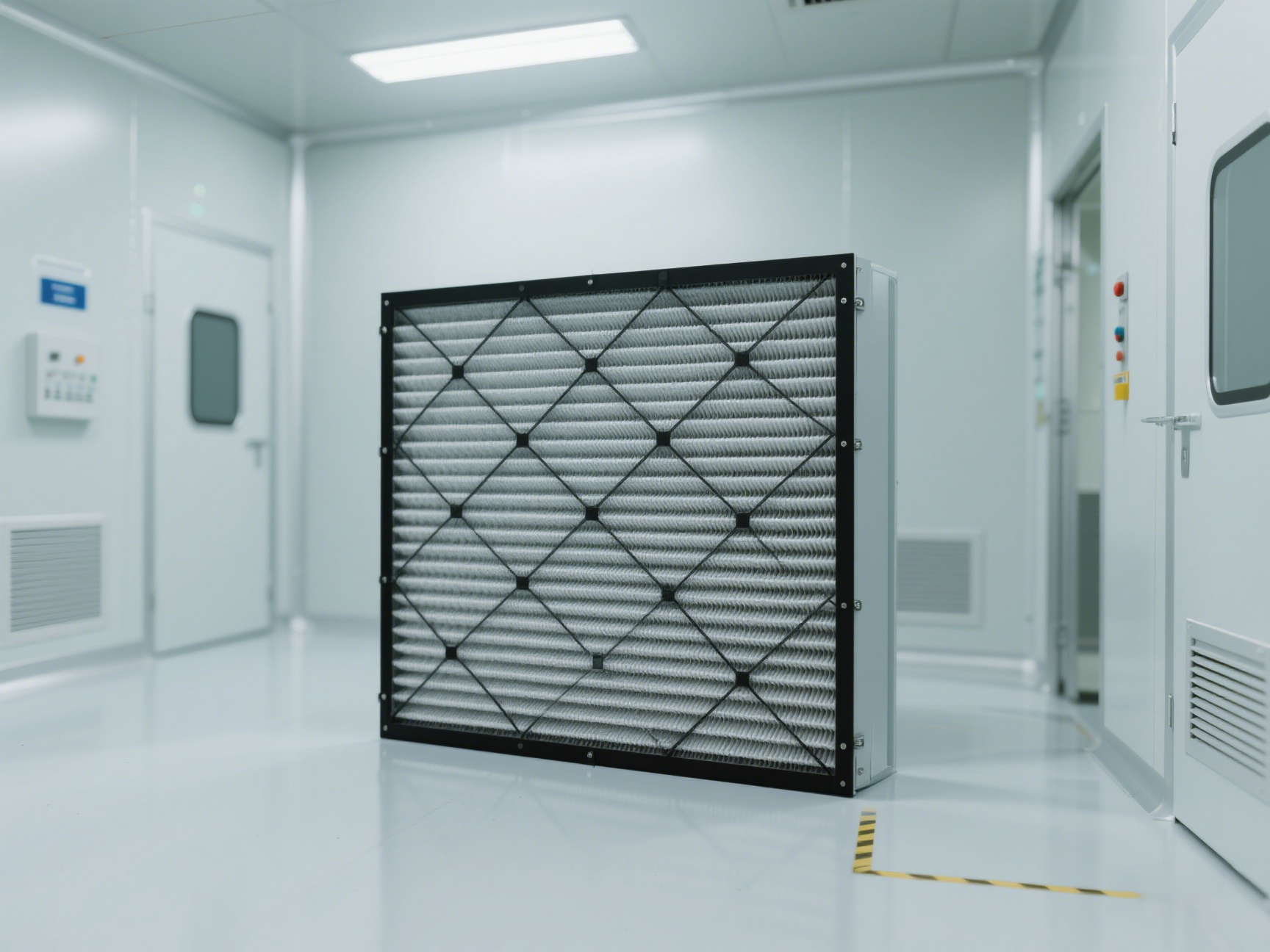

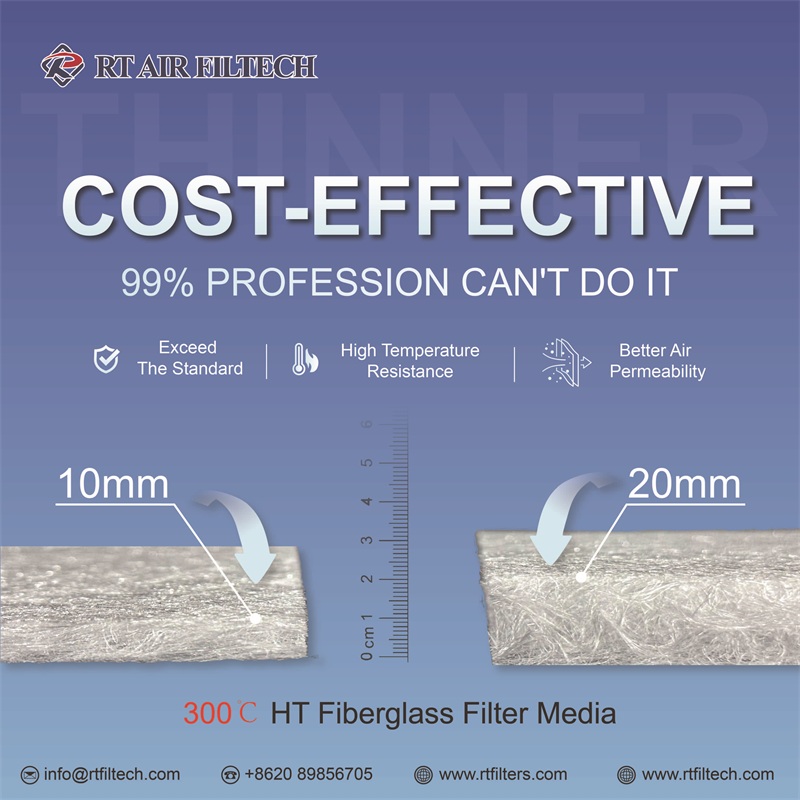

We have a new panel filter that is resistant to high temperatures up to 300°C, achieving a thinner thickness of 10-20mm and lower resistance.

One of its greatest advantages is affordability. When using a 20mm-thick plate filter, you may need to compress 30mm-thick filter media down to 20mm. This means purchasing 30mm media upfront, even though the final requirement is thinner. It's worth noting that the industry standard thicknesses for filter media are typically 30mm and 50mm.

Feature | Pleated Filter | Non-Pleated Filter |

Surface Area | 3x–5x | 1x |

Dust Holding Capacity | 3x–5x | 1x |

Filtration Efficiency | G4-F9 | G2-G4 |

Lifespan | 2x | 1x |

Initial Cost | 1.2x | 1x |

Maintenance Frequency | Lower | Higher |

Wind Resistance | Higher | Lower |

Energy Savings | Higher ΔP increases energy use | Lower ΔP = 5-15% fan energy reduction |

In many industries, non-pleated and pleated air filters are deployed in tandem within the same ventilation system to optimize performance, cost, and maintenance efficiency. This multi-stage filtration strategy leverages the strengths of each filter type at different points in the airflow pathway.

Industry | Pleated Filters | Non-Pleated Filters |

Manufacturing | Cleanrooms, electronics | Pre-filters in workshops |

Automotive | Final-stage spray booth filters | Floor/ceiling pre-filters |

Commercial HVAC | High IAQ zones | Temporary or low-budget installs |

Food & Beverage | Packaging zones | HVAC pre-filters |

Energy / Utilities | Protect sensitive equipment | Large-scale pre-filtration |

Warehousing | Offices, high-use zones | Open storage areas |

1. Lower Air Resistance (ΔP) = Higher Airflow Efficiency

Non-pleated filters have a flat, single layer design, creating minimal obstruction to airflow.

Pleated filters, with their folded media, increase surface area but also add resistance (higher pressure drop). In systems where airflow volume is critical (e.g., data centers, industrial exhaust), non-pleated filters reduce fan energy consumption by 5–15% compared to pleated filters.

2. Ideal for High-Velocity Systems

Applications like paint booths, welding fume extractors, and server cooling require high CFM (cubic feet per minute) rates. Non-pleated filters prevent airflow bottlenecks, ensuring consistent ventilation. Such as, data center using MERV 4 fiberglass filters avoids overheating servers by maximizing cooling airflow.

3. Cost-Effective for Bulk Particle Capture

If the goal is stopping large debris (dust, lint, insects) without needing fine filtration, non-pleated filters are cheaper to install and replace. Construction sites use disposable fiberglass filters to protect HVAC systems from coarse dust.

4. Short-Term & Temporary Applications

Low dust-holding capacity isn’t an issue if filters are replaced frequently (e.g., monthly).

1. Higher Surface Area = Better Particle Capture

Pleated filters triple or quadruple the media surface area via folds, trapping more and smaller particles.

MERV 8–16 pleated filters capture:

Pollen, mold spores (MERV 8–11)

Bacteria, smoke (MERV 12–13)

Viruses (MERV 14–16, HEPA)

2. Essential for Health & Safety Compliance

Hospitals, labs, and food plants require MERV 13+ to meet air quality standards.

3. Longer Lifespan in Dusty Environments

Pleated filters hold 2–3x more dust before clogging vs. non-pleated. Critical for factories, woodshops, and mining, where replacing filters frequently is impractical.

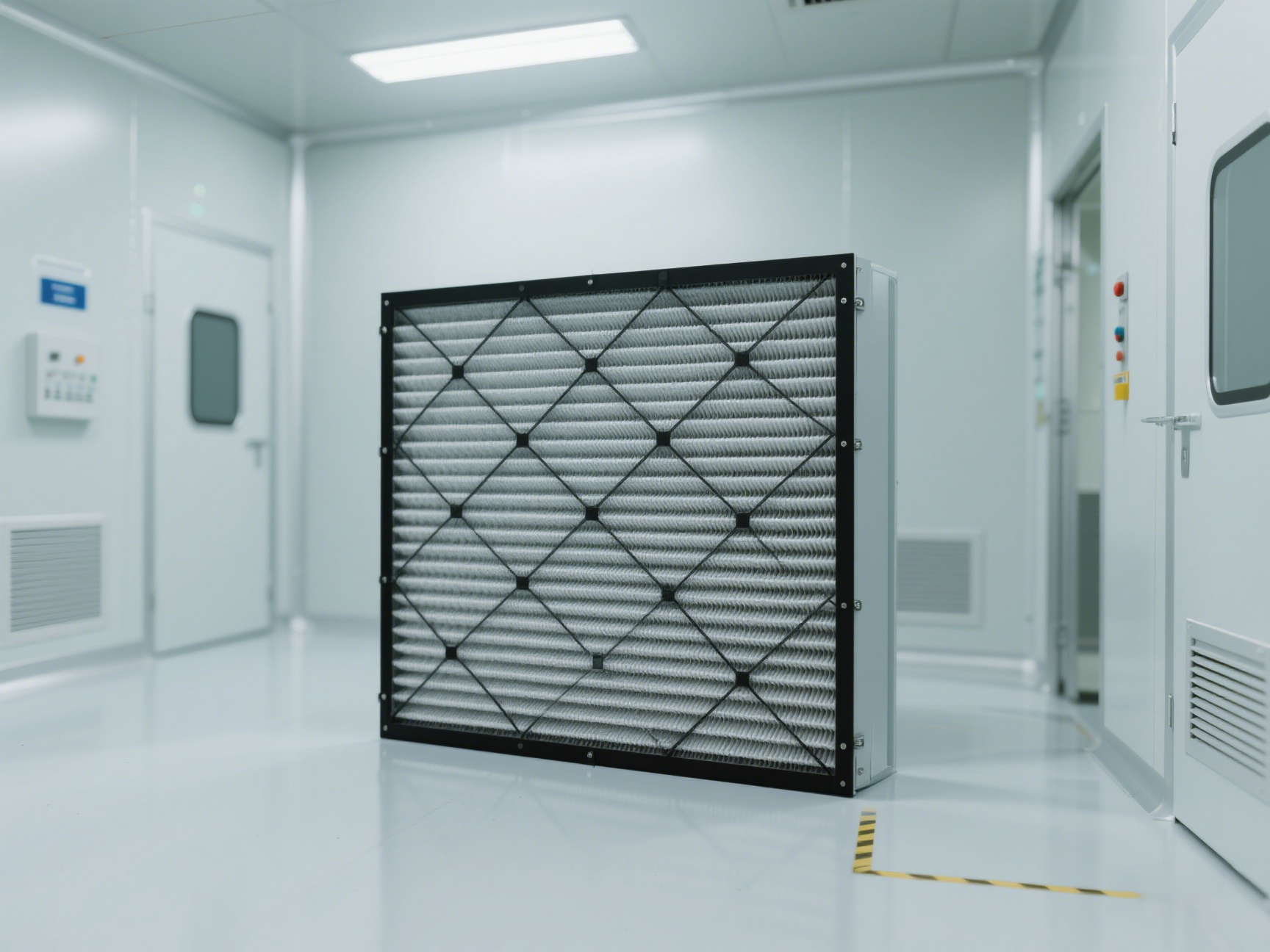

4. Precision Filtration for Sensitive Equipment

Electronics manufacturing (e.g., semiconductor cleanrooms) demands sub-micron filtration to prevent micro-contamination.

The debate between non-pleated vs. pleated filters isn't just about cost or efficiency—it's about adapting to a world where air quality matters more than ever.

For industrial leaders, the choice impacts energy bills, compliance, and equipment longevity.

For healthcare providers, it's a life-or-death decision for infection control.

For everyday consumers, it's about healthier homes and workplaces.

Your Next Step?

Test your air.

Audit your system.

Think ahead.

The air you filter today shapes the environment of tomorrow. Choose wisely-and breathe easier.

Need a custom solution? Tell me your industry's biggest air challenge, and let's design the right filter strategy.