HVAC systems rank among the largest energy consumers in modern buildings, typically accounting for one-third to half of total electricity usage. As energy costs continue to increase, many facility managers focus their attention on motors, ductwork, or control systems, rarely realizing that air filtration systems are one of the hidden causes driving up energy consumption. Particularly, the selection and maintenance practices for bag filters directly impact air resistance, system pressure, and overall energy efficiency.

An improperly sized or poorly performing filter can silently inflate monthly electricity bills. Conversely, a well-chosen filter can significantly reduce operating costs.

ISO 16890 is an international air filtration standard used to classify filters based on how effectively they capture particles between 0.3 and 10 microns.

Unlike older systems that relied on a single test point, ISO 16890 evaluates performance across the full range of particulate matter found in real environments.

Its biggest advantage is that it aligns with global air quality terminology such as PM1, PM2.5, and PM10, making it far easier to match filters with real-world air quality needs.

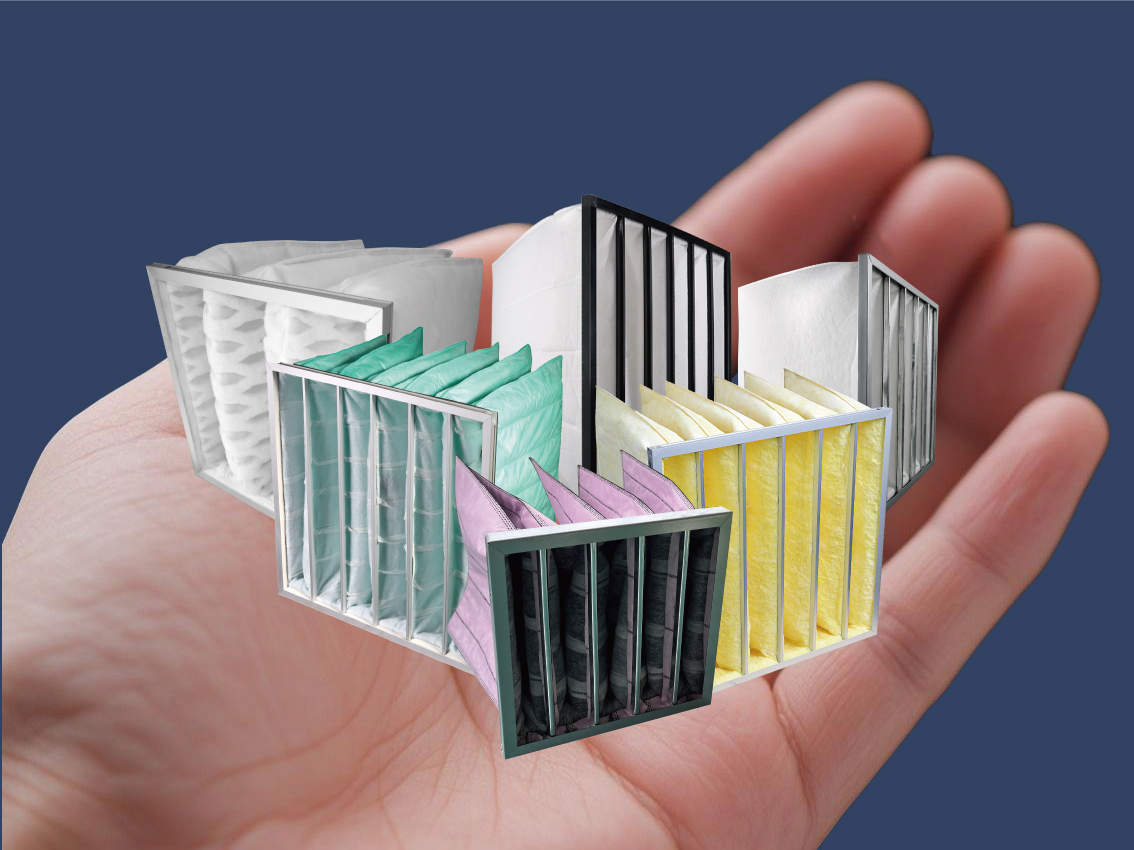

Bag filters are widely used in commercial buildings, manufacturing plants, hospitals, spray booths, livestock barns, and other environments requiring stable airflow and mid-to-high efficiency filtration.

ISO 16890 provides several improvements that help users pick the right bag filter:

More realistic performance evaluation

Better alignment with environmental dust types

Clear efficiency categories for easier comparison

Improved accuracy for fine-particle filtration (PM1)

Better global consistency for HVAC and industrial systems

For buyers and engineers, it removes guesswork and simplifies filter selection.

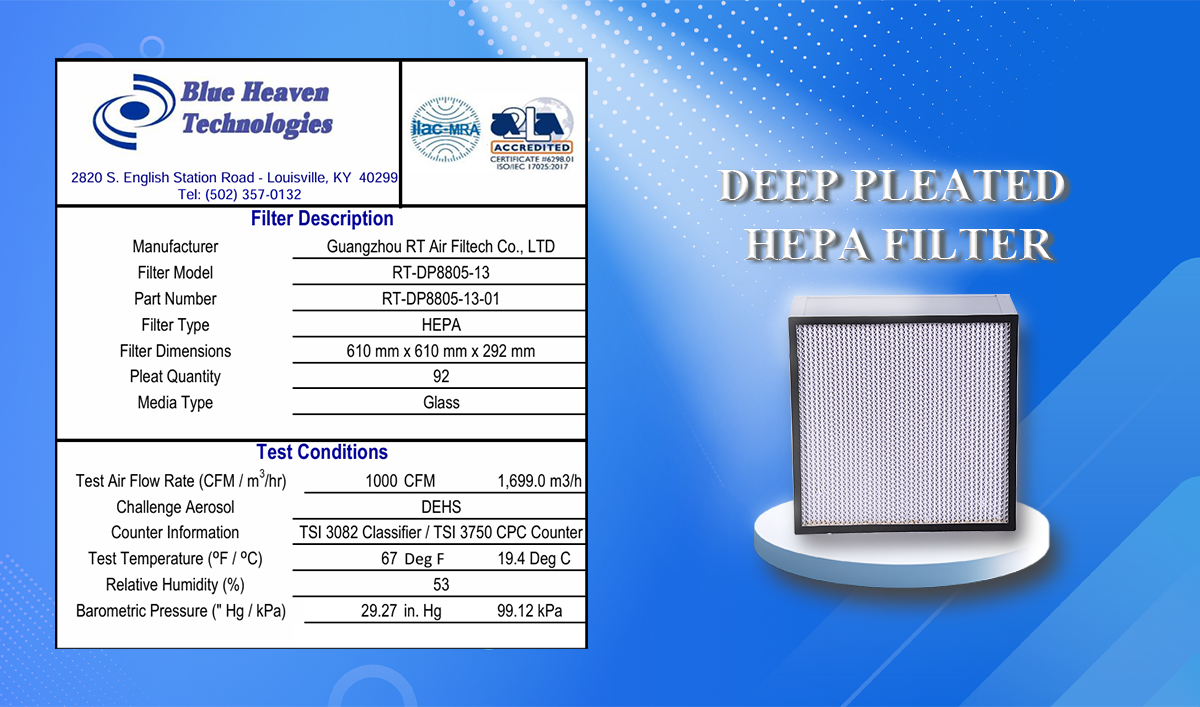

ISO 16890 evaluates filters in two main stages:

Filters are tested using a particle counter to measure how well they capture particles from 0.3 to 10 microns.

Filters are exposed to an electrical discharge to neutralize the electrostatic charge.

This is critical because many synthetic bag filters use static charge to improve performance. Without discharge testing, results would be overly optimistic.

The final rating reflects the average real-life performance—not the temporary electrostatic boost.

ISO 16890 divides filters into four groups, based on their minimum efficiency for each particle size category.

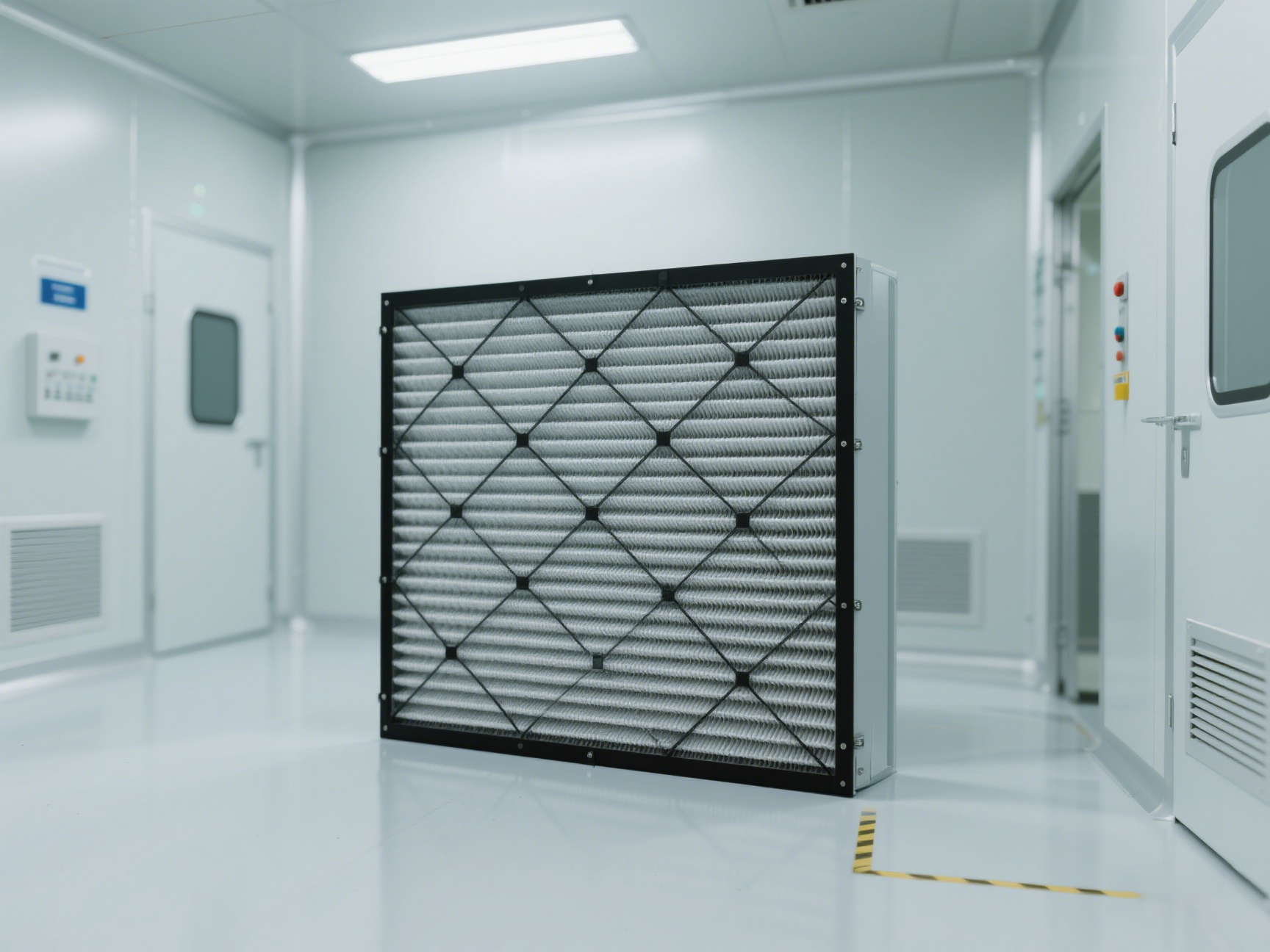

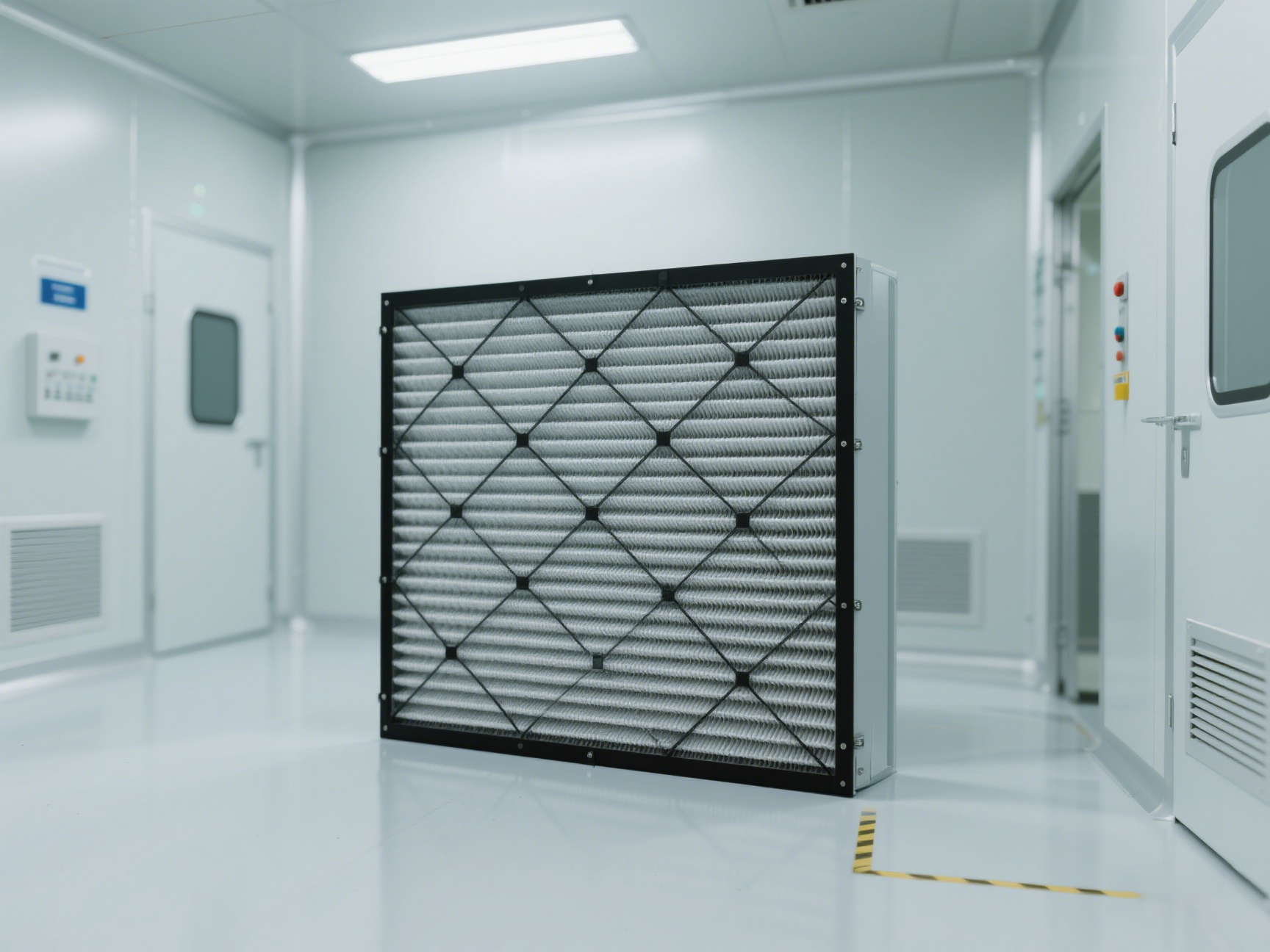

Captures fine particles smaller than 1 micron. Ideal for:

hospitals

clean processing rooms

hotels & airports

high-performance HVAC systems

Captures particles between 1 and 2.5 microns. Common in:

offices

commercial buildings

general ventilation

Captures coarse dust between 2.5 and 10 microns. Used in:

warehouses

industrial workshops

pre-filtration for higher-grade filters

Captures large particles but less than 50% of PM10. Used in:

rough industrial environments

Basic dust filtration

Pre-filter stages

A typical mid-efficiency bag filter falls under ePM2.5 or ePM10. High-performance bag filters often meet ePM1.

ISO 16890 clarifies which filter performs best under different air quality conditions.

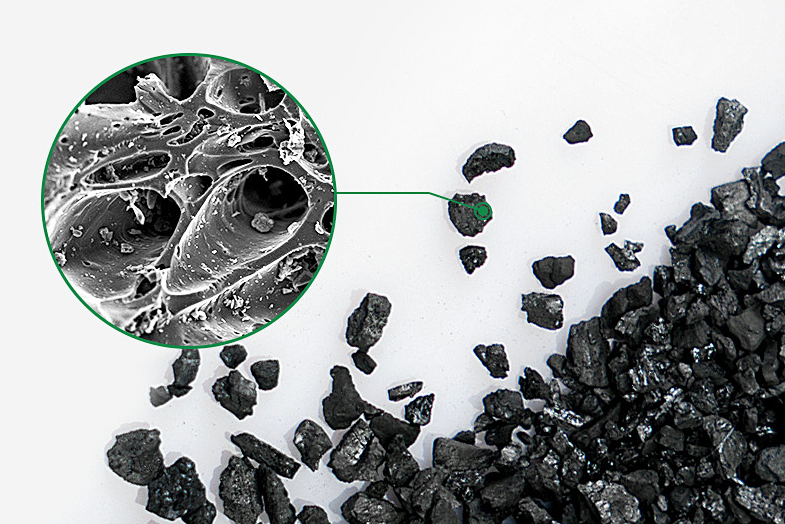

For example, a pig barn with a high PM10 load should not use a PM1 filter, as it would clog too quickly.

A hospital, on the other hand, requires PM1 for fine airborne contaminants.

Because users can select a filter that suits the actual dust environment, bag filters are less likely to overload or clog prematurely.

HVAC energy use depends heavily on pressure drop.

ISO 16890 provides realistic performance data, making it easier to estimate energy cost and plan replacement cycles.

Many countries are transitioning to ISO 16890 to standardize filtration requirements.

This simplifies exports, procurement, and equipment compatibility.

Here are simple guidelines for selecting bag filters:

Use ePM2.5 50–70% bag filters.

They strike a balance between airflow, durability, and efficiency.

Use ePM10 50–65% bag filters.

They handle coarse dust without clogging too quickly.

Use ePM1 60–85% bag filters.

They capture the smallest airborne contaminants.

Use ISO Coarse as a pre-filter, followed by ePM2.5 or ePM1.

Understanding ISO 16890 is essential for anyone purchasing, designing, or maintaining HVAC systems. With the right bag filter and correct efficiency class, you can greatly improve system performance and long-term operating costs.