In cleanroom construction and operation, selecting the wrong FFU (Fan Filter Unit) can silently eat away your budget and compromise production quality.

One semiconductor company suffered a 15% spike in product rejection rates in a single quarter due to miscalculated air volume, while a pharmaceutical firm saw its energy expenses exceed projections by 40% after blindly investing in over-specified FFUs.

From microelectronics to pharmaceuticals to food processing, FFU selection isn't just a technical decision—it's a strategic one. Done right, it ensures cleanroom performance, cost efficiency, and operational stability. Done wrong, it can trigger a cascade of hidden costs and production failures.

Here's a 5-step selection method, based on industry best practices, to help you make the right FFU choices the first time.

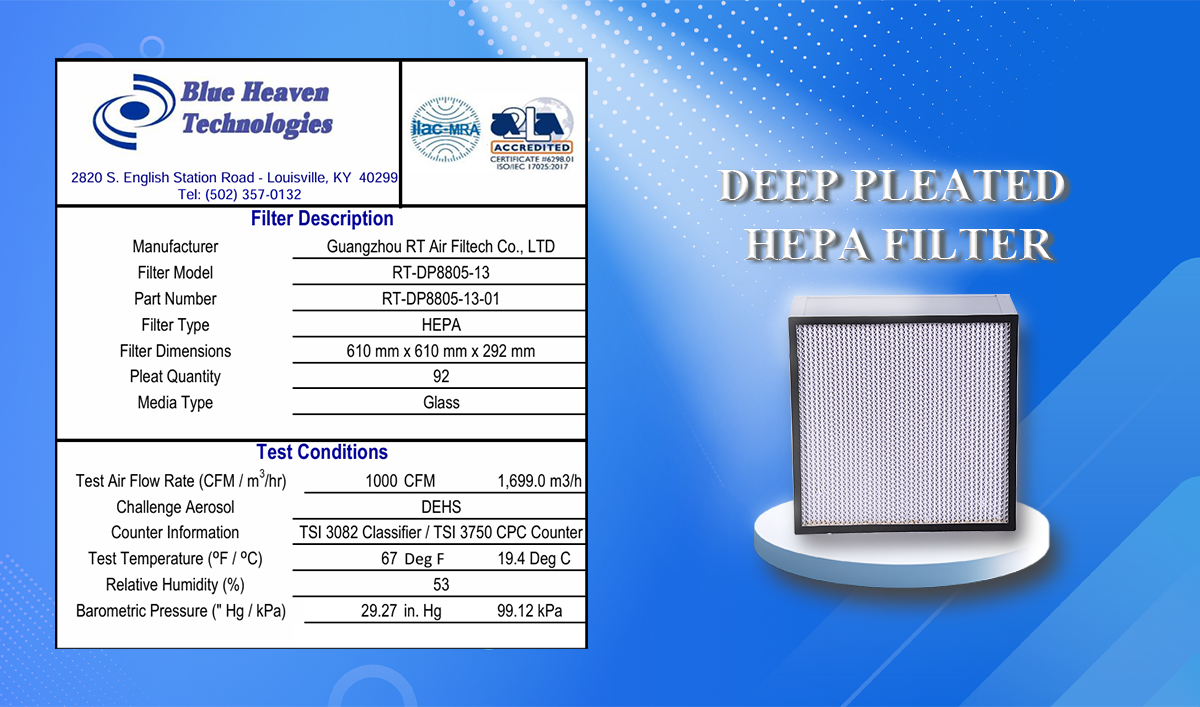

The ISO 14644 standard classifies cleanrooms from ISO Class 1 (ultra-clean) to ISO Class 9 (less stringent). Your required cleanroom class determines the minimum efficiency of the filter:

ISO Class 5 (equivalent to Class 100)

Used in semiconductor lithography and high-precision optics. Requires HEPA filters rated H13 or higher, with ≥99.97% efficiency for particles ≥0.3μm.

ISO Class 7 (equivalent to Class 10,000)

Common in electronics assembly and food packaging. H11 filters are typically sufficient when combined with appropriate airflow design, helping reduce both initial and operational costs.

Each industry has its own cleanroom sensitivities. Misjudging these can lead to severe performance issues:

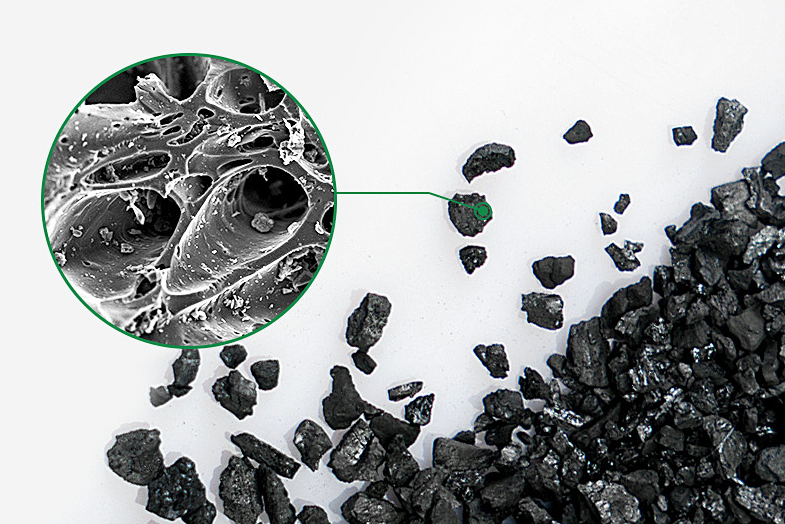

Pharmaceuticals: Prioritize airtight sealing and microbial control. Look for FDA-grade stainless steel housings and EVA sealing gaskets to prevent contamination.

Photovoltaics (PV): Manufacturing often emits corrosive gases. If FFU materials lack corrosion resistance, components may rust or leak in less than a year. Anodized aluminum or coated materials are a must.

Tip: Always match FFU material and design with the cleanroom’s process environment—not just the air cleanliness class.

Air volume calculation is at the heart of FFU selection. Overestimating leads to energy waste; underestimating risks cleanroom compliance.

Determine Air Change Rate (ACR)

Based on ISO class and industry norms. For example, ISO Class 6 (Class 1,000) typically requires ≥50 air changes per hour.

Calculate Total Air Volume

Use the formula:

Air Volume (m³/h) = Area × Ceiling Height × ACR × Safety Factor

Example: A 100 m² cleanroom with 3m ceiling, 50 ACR, and 1.2 safety factor:

→ 100 × 3 × 50 × 1.2 = 180,000 m³/h

Determine FFU Quantity

If one FFU provides 1,200 m³/h, you'll need:

→ 180,000 ÷ 1,200 = 150 units

Some suppliers inflate airflow ratings to lower perceived costs. To protect yourself:

Ask for third-party test reports;

Visit reference sites to observe real-world FFU performance.

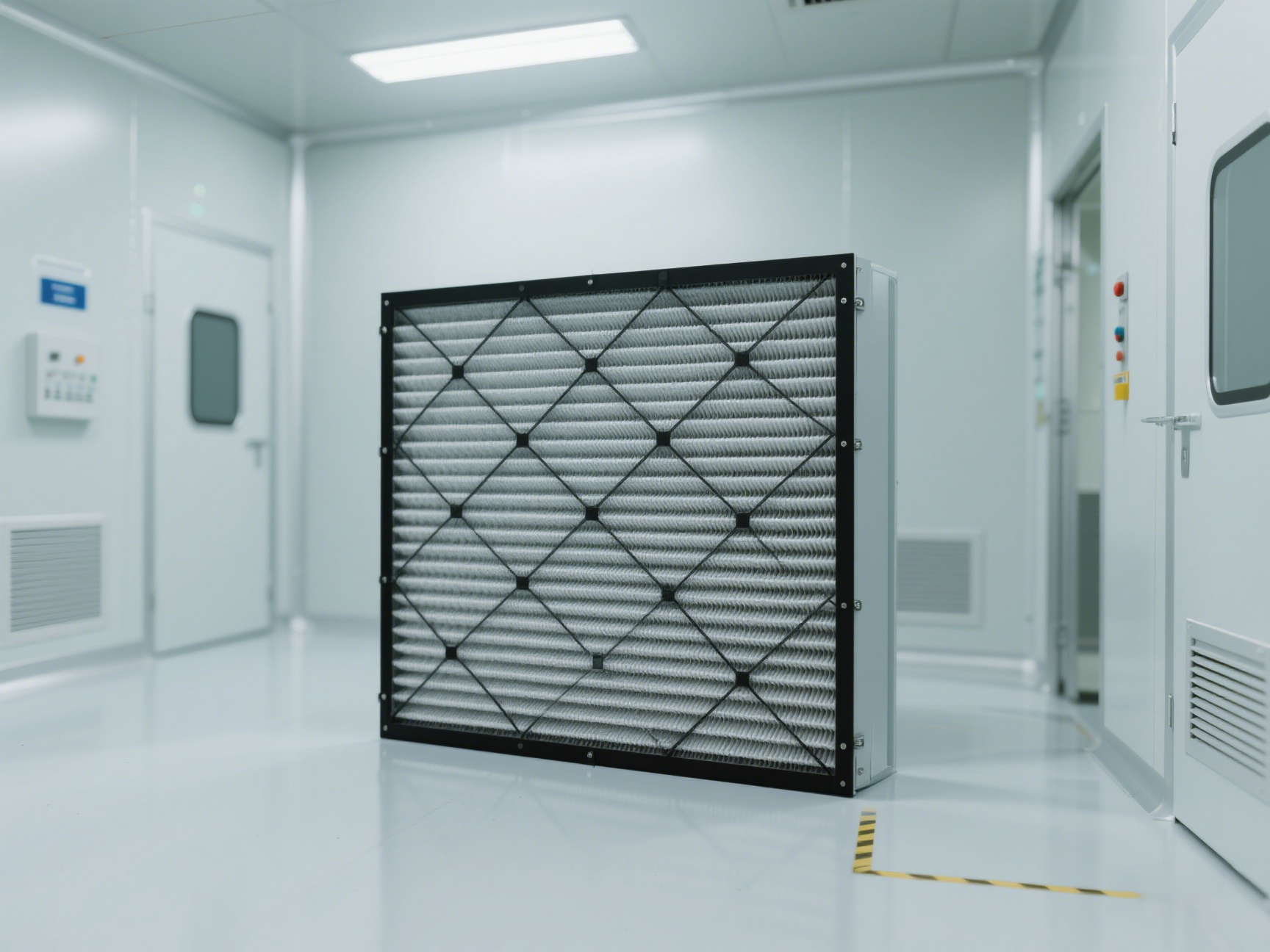

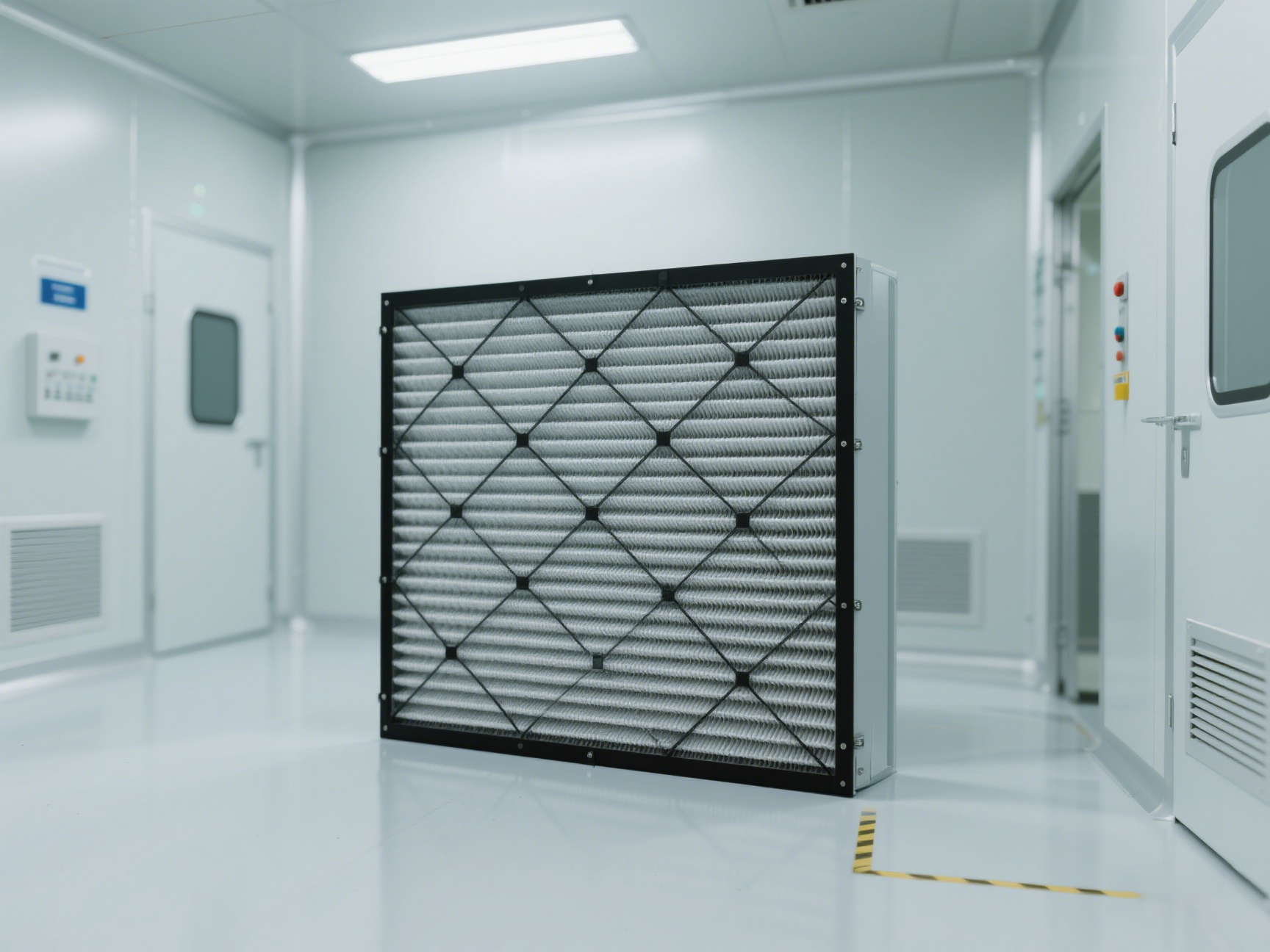

Mismatched Cleanroom FFU components can shorten lifespan or compromise cleanroom performance.

Fan PQ curve: Shows fan output at various static pressures.

Filter resistance curve: Shows pressure drop across the filter over its life cycle.

Goal: The FFU’s working point should fall at or near the intersection of both curves.

Example: The fan provides 1,200 m³/h at 200 Pa; the filter’s full-load resistance is 180–220 Pa. Perfect match.

For facilities with fluctuating demands, opt for EC (Electronically Commutated) motors with speed control. Benefits include:

Adapts to different zones or processes;

Saves energy;

Extends filter life by avoiding unnecessary overpressure.

Upfront savings often translate into long-term expenses if FFUs are poorly chosen.

AC motors: Basic but power-hungry.

EC motors: Energy-efficient and intelligent, saving 30–50% in power consumption.

Conventional FFUs often require tools and take 30 minutes per unit to replace filters.

Modern FFUs with tool-free quick-release mechanisms cut that time to under 5 minutes, saving labor and downtime.

Brochures and spec sheets only tell part of the story. To reduce risk:

Ask for 3+ real-world projects in your industry with the same ISO class;

Prioritize installations with over 3 years of uptime and no major failures;

Request client feedback on noise, airflow stability, and energy performance;

If available, review electricity bills or energy reports to verify promised savings.

Pro tip: On-site visits and direct calls to reference clients can be more insightful than any datasheet.

By following these 5 steps, you’ll be able to select the right FFU solution for your cleanroom—whether for a greenfield project or an upgrade retrofit. The right choice leads to:

Optimal cleanroom compliance;

Lower operational expenses;

Better production stability;

A smoother, more confident procurement process.

So next time you’re selecting FFUs, remember:Choose smart. Choose right. Clean, efficient, and future-ready.