Filters are essential for ensuring air quality across various environments, including residential, commercial, and industrial settings. Understanding the global standards for pre-filters, medium-filters, and high-efficiency filters is crucial to making the right filtration choice. This article delves into the standards for these filters by region and provides examples of their usage.

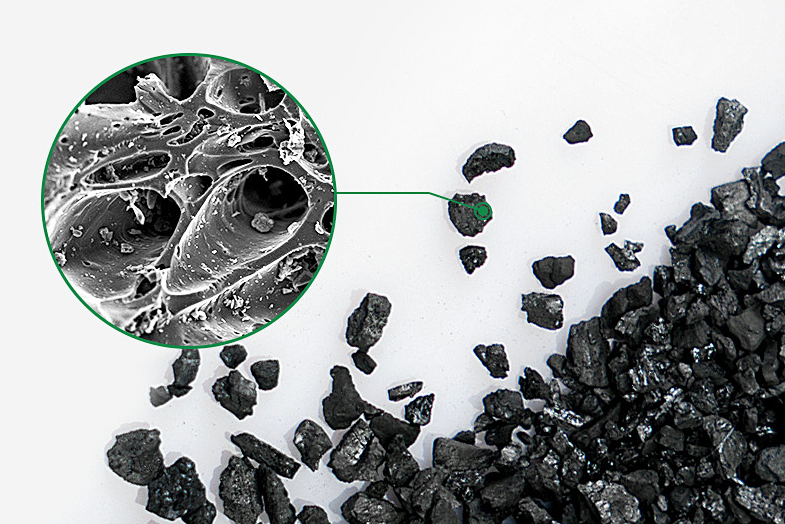

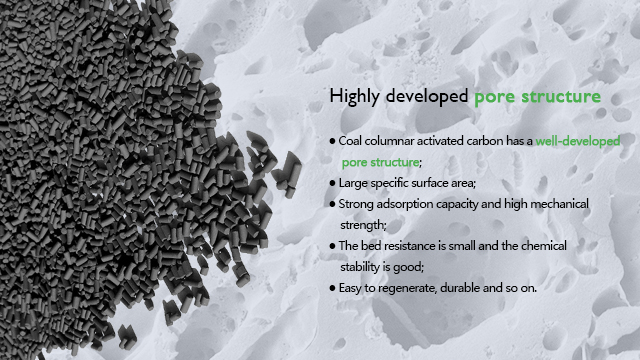

Pre-Filters: Capture larger particles like dust and pollen, preventing debris from clogging more sensitive filters.

Medium Filters: Remove smaller particles, typically around 1 micron in size, used in environments where moderate air quality is needed.

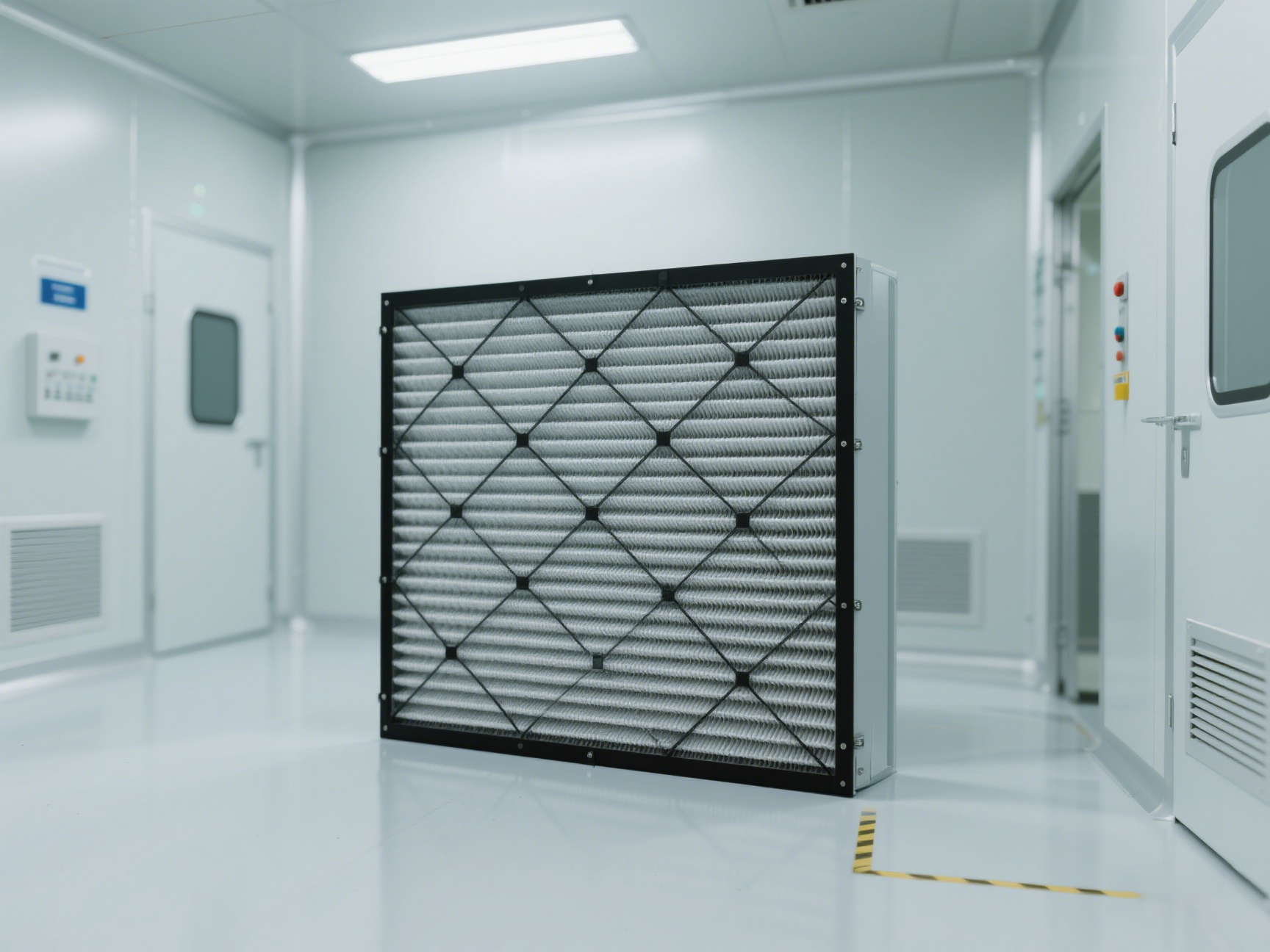

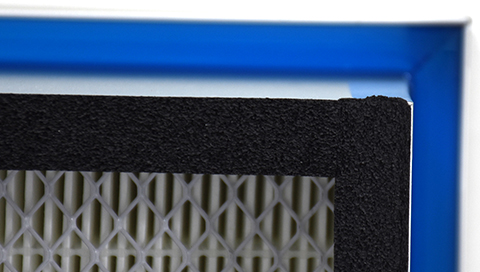

High-Efficiency Filters (HEPA & ULPA) Capture very fine particles, as small as 0.3 microns (HEPA) or even smaller (ULPA). They are crucial for high-precision environments such as hospitals and cleanrooms.

In the U.S., the ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers) standards are widely used to classify filters based on their MERV (Minimum Efficiency Reporting Value). MERV ratings range from 1 to 16, with higher values indicating better filtration.

Pre-Filters: MERV 1-8. These filters provide basic protection in residential and light commercial applications. They capture larger particles such as dust and pollen.

Medium Filters: MERV 8-15. Filters in this range are designed for better air quality in environments such as offices, schools, and hospitals.

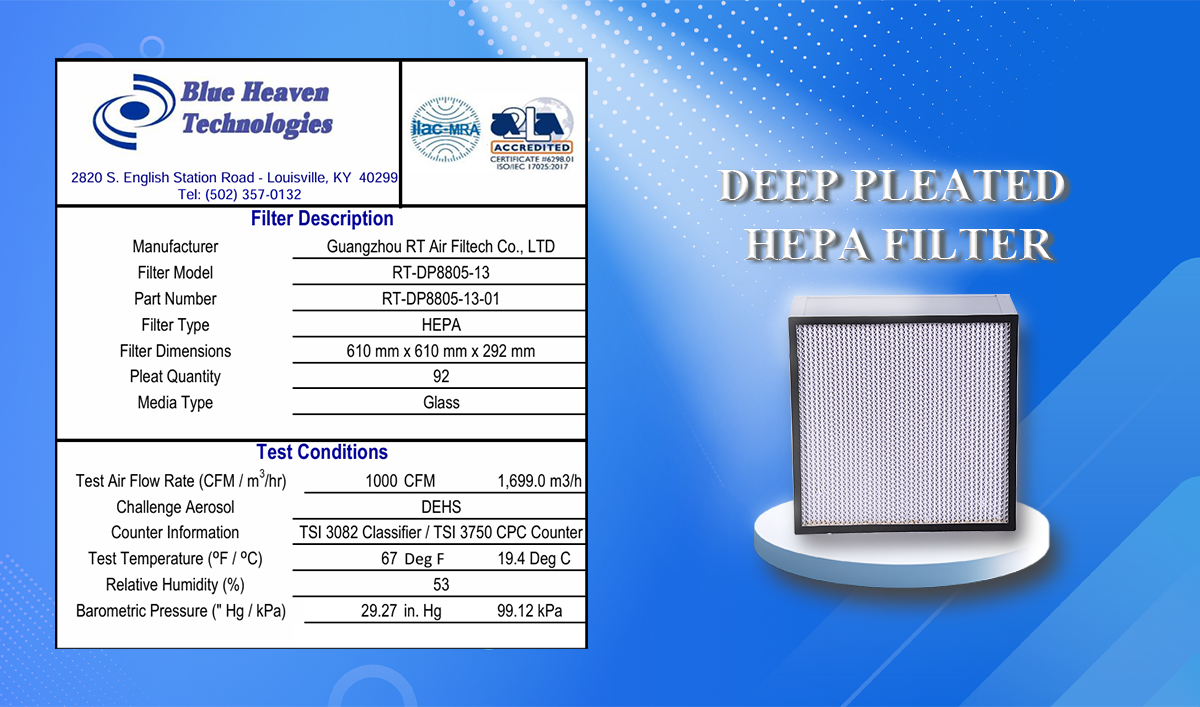

HEPA Filters: HEPA filters must meet the IEST-RP-CC001.3 standard, capturing at least 99.97% of particles 0.3 microns or larger. These are essential in cleanrooms and medical facilities.

Europe uses the EN 779 standard for air filters, which classifies filters based on their ability to remove particles larger than 0.4 microns. For high-efficiency filtration, EN 1822 governs HEPA and ULPA filters, with a focus on removing very fine particles.

Pre-Filters: G1-G4. These are used to remove large particles and are commonly found in industrial and commercial environments.

Medium Filters: F5-F9. Filters in this range are used in public buildings, offices, and malls.

HEPA Filters: H13-H14. These filters remove 99.95% of particles and are used in cleanrooms, hospitals, and laboratories.

ISO 16890 is the globally recognized air filter standard, replacing EN 779 and providing a more comprehensive evaluation of filters based on real-world performance. The classification is based on the filter’s ability to remove particles of different sizes:

ISO Coarse (Pre-Filters): Removes larger particles (PM10 and above), typically used in industrial and commercial buildings.

ISO ePM10 (Medium Filters): Captures particles in the PM10 range, commonly used in HVAC systems.

ISO ePM2.5 (High-Efficiency Filters): Filters smaller particles in the PM2.5 range, used in hospitals and office spaces.

ISO ePM1 (HEPA-Level Filters): Traps ultrafine particles in the PM1 range, suitable for high-precision environments.

GUANGZHOU RT AIR FILTECH CO., LTD is a leader in the filter manufacturing industry, offering products that comply with MERV, EN, and GB/T standards. Their filters serve various sectors, including healthcare, industrial environments, and HVAC systems. RT Air Filtech provides high-quality pre-filters, medium filters, and HEPA filters, ensuring clean air in critical environments.

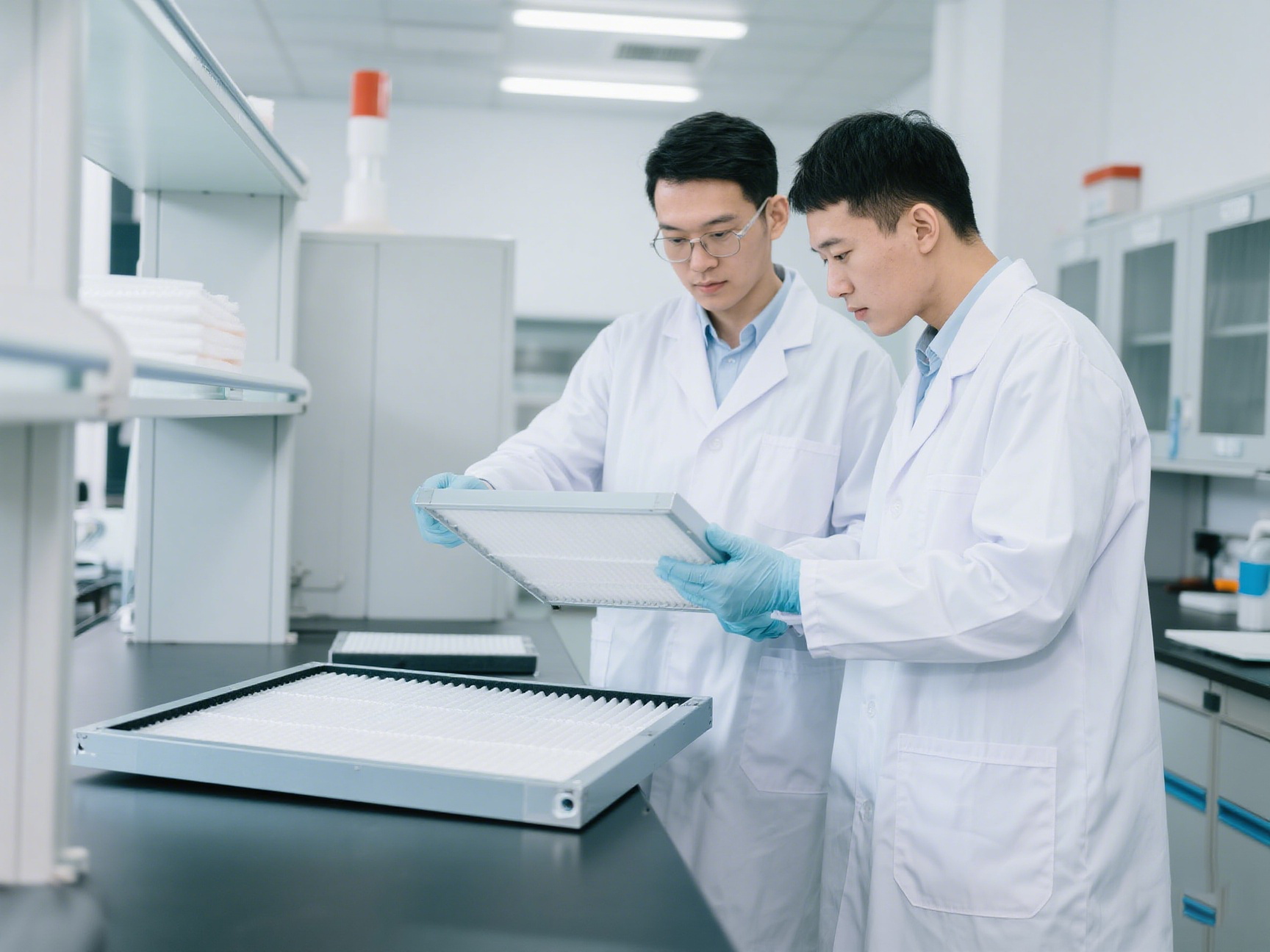

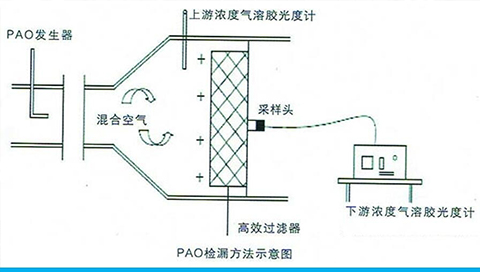

Filters undergo several tests to confirm their performance:

Particle Counting: Measures the concentration of particles before and after filtration, ensuring efficiency.

Pressure Drop Testing: Assesses the airflow resistance across the filter while maintaining filtration efficiency.

Dust Loading Tests: Simulates long-term usage by loading the filter with dust particles to measure performance over time.

Understanding the standards for pre-filters, medium filters, and high-efficiency filters is essential for selecting the right solution for any environment. GUANGZHOU RT AIR FILTECH CO., LTD offers filters that meet global standards, ensuring optimal air quality and system performance in hospitals, offices, industrial spaces, and more.