Two of the most important components of successfully running a paint booth are efficiency and quality. Being able to get the most out of your paint booth is key for body shops and collision centers, as they’re expected to complete projects quickly while providing a consistently excellent product. Maintenance is a strong guarantee that the equipment will operate at its best, and one of the most important components to keep the equipment in top condition is the filtration system.

|

While it may not seem like much on the surface, using old filters cost you a lot of money down the road. A clogged filter cannot absorb all the dust and debris floating around the paint booth. This means that contaminants that are not extracted by the filter system may remain on the new paint and have to provide an additional layer of paint to the product in order to ensure the quality of the product. In addition, over time, this may lead to equipment failure.

How to choose the right filter

When replacing spray booth filters, not just any filter is used. After all, the purpose of a filter is to protect the sensitive mechanical parts in a paint booth from harmful contaminants. For this reason, you need to choose a filter that is of good quality and has a high efficiency and long life.

Some of the things you need to be aware of when choosing a filter:

1、The thickness of the filter

2、The way the filter is designed

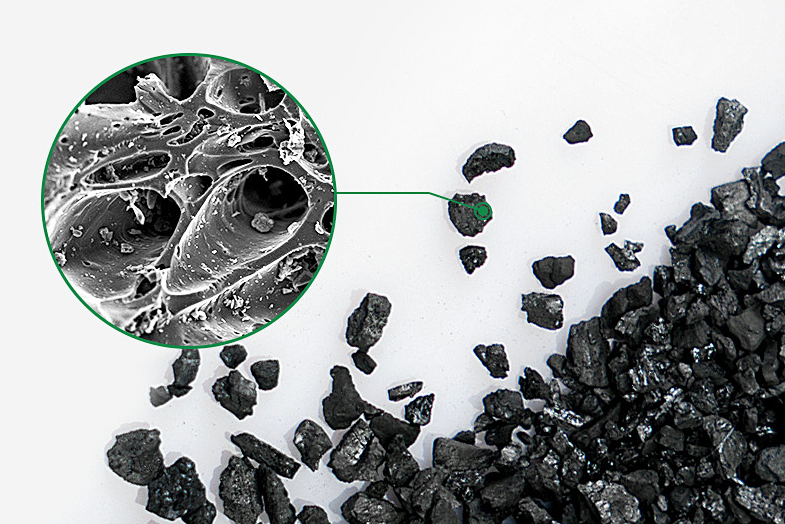

3、The filter’s fiber composition

4、The loft rating of the filter

When you start shopping around for new paint booth filters, make sure that you choose one that can give you the balance you need to run your paint booth at its best. This means that you must find a filter that’s able to block out harmful contaminants while still being able to give your equipment the airflow that it needs to run at its best.

|

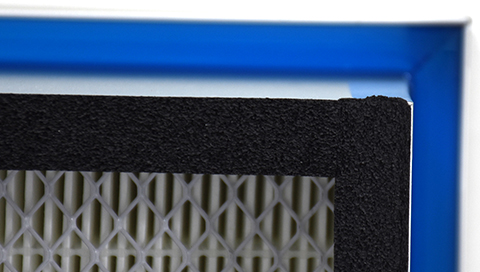

What are the different types of filters for paint booths

Choosing a filter for a paint booth is not an easy task. Many people mistakenly underestimate the important role that filters play in maintaining the life of a paint booth. Everything from the quality of the finished product to the speed at which the job is completed is affected by the filter, so it is vital to keep it clean and up to date.

The following are the types of filters that can be found in a paint booth.

1. Air makeup filters

Air makeup filters are located in the make-up air unit of the paint booth. These filters play an important role in protecting the paint booth from contaminants in the air system and other working parts that can damage the equipment. By preventing large particles from entering the air system, make-up air filters ensure that the air pressure in the paint booth is at an optimal level.

|

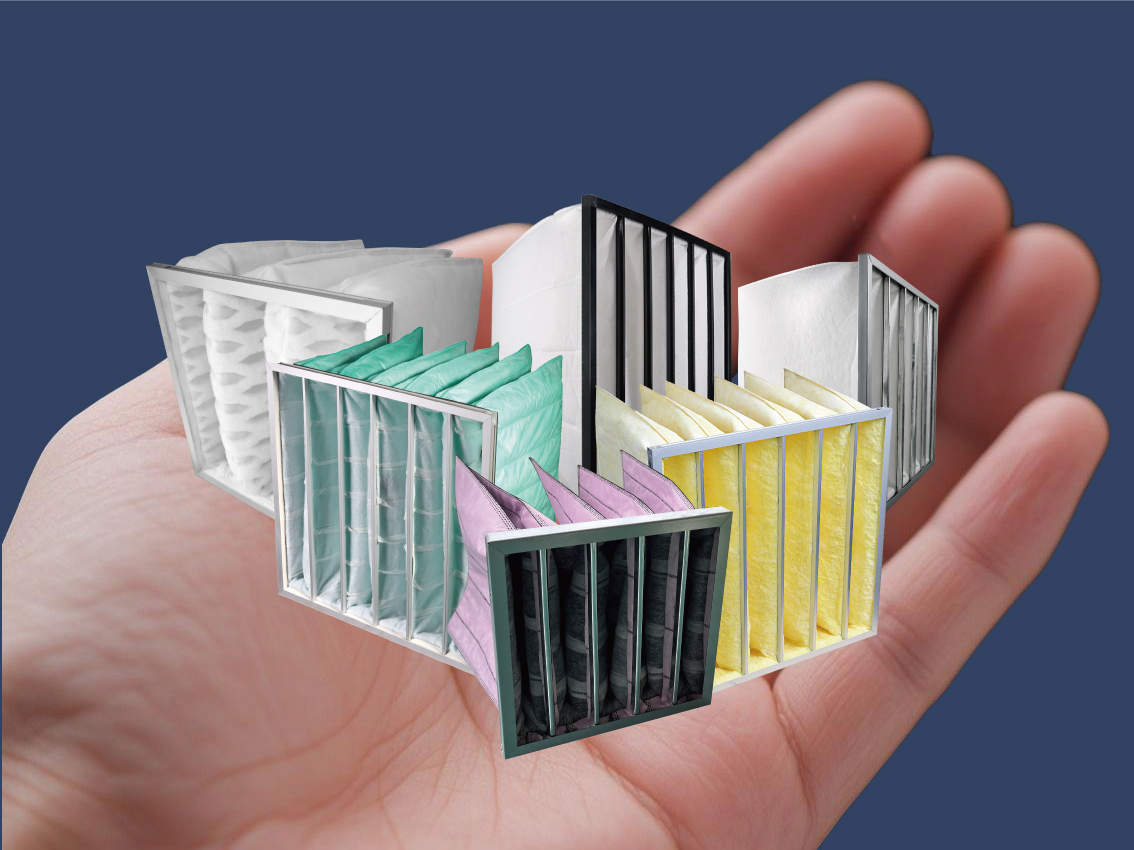

High-quality make-up air filters with high fluffiness ratings ensure the longevity of the paint booth. They are available in a variety of styles, including pads, panels, reusable aluminum filters and bag filters. When it's time to replace your make-up air filter, make sure the filter you choose provides adequate airflow. If you are experiencing airflow problems in your paint booth, your first concern should be the make-up air filter. Often, the solution is to replace the filter with a suitable one.

2. Intake air filters

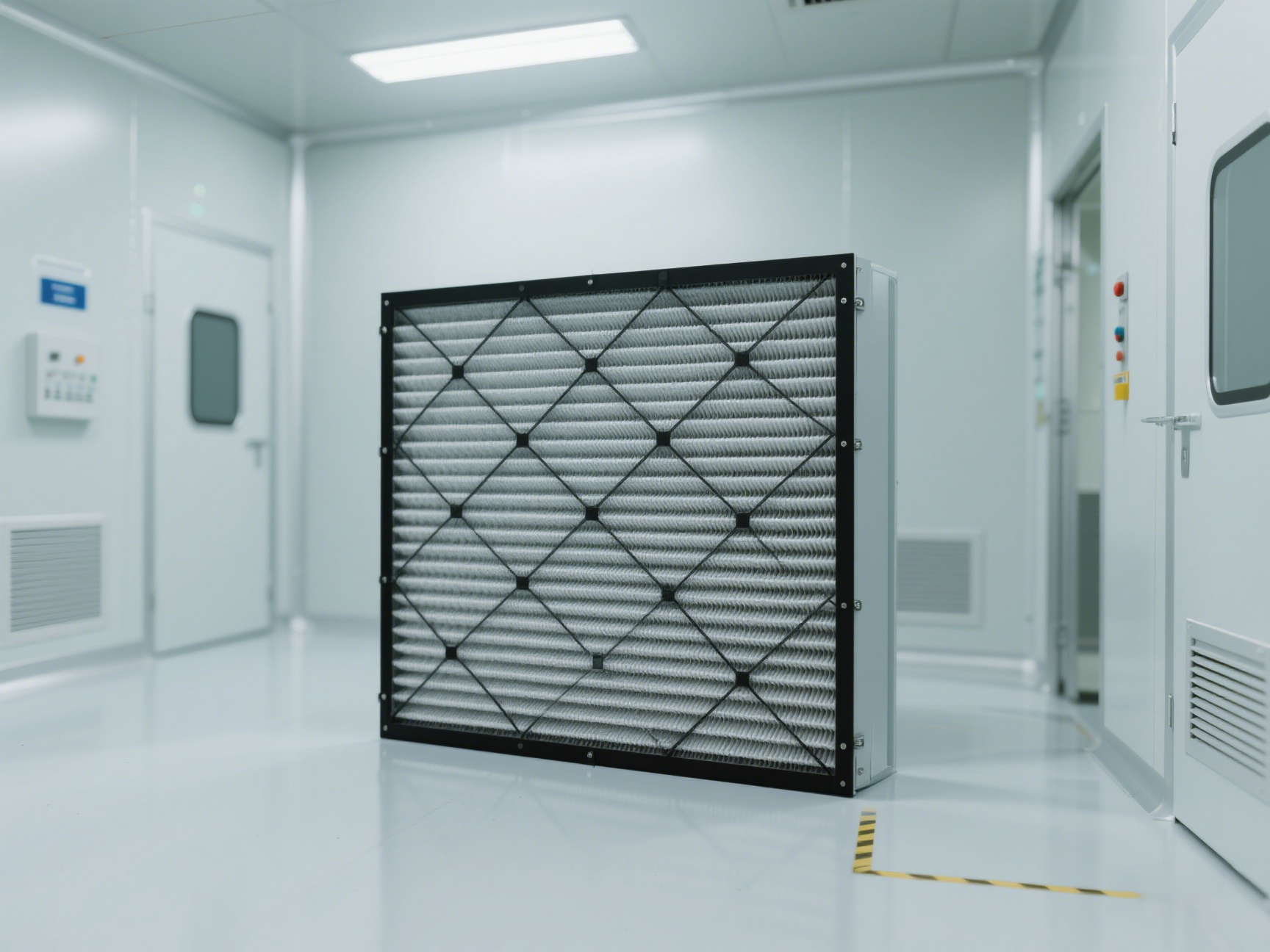

In actual production, a single particle of dust invisible to the naked eye is enough to completely destroy the work that is about to be done. For paint booths, a clean environment is a central concern, as even the smallest amount of debris contamination can make production very expensive and require re-production - which is why paint booths use intake filters.

The intake filter is designed to remove all contaminants from the paint booth so that you get a clean, smooth surface every time. For downdraft spray booths, intake filters also help to draw dust away from the object being painted, thus minimizing the risk of soiling, streaking and splattering.

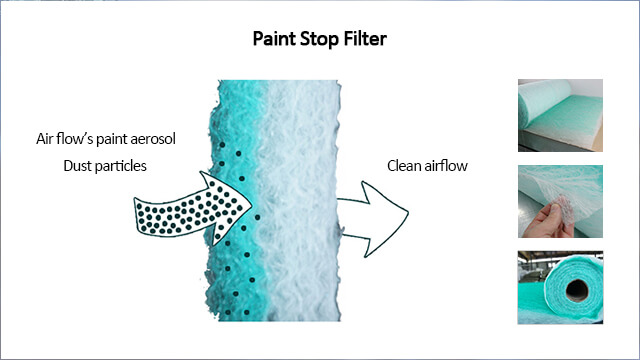

3. Exhaust filters

The third type of filter is the exhaust filter. While it does not have much impact on the quality of the finished product, maintenance of this type of filter is equally important. The job of the exhaust filter is to ensure that the air leaving the paint booth is clean and free of any hazardous chemicals and vapors. Working for long periods of time around a paint booth with a poorly maintained exhaust filter can endanger one's health.

In addition, exhaust filters also have to be installed in place to protect the equipment's fans from overspray buildup. To do this successfully, it is necessary to choose a filter that is durable enough to be exposed to paint for extended periods of time without having to be replaced.

|

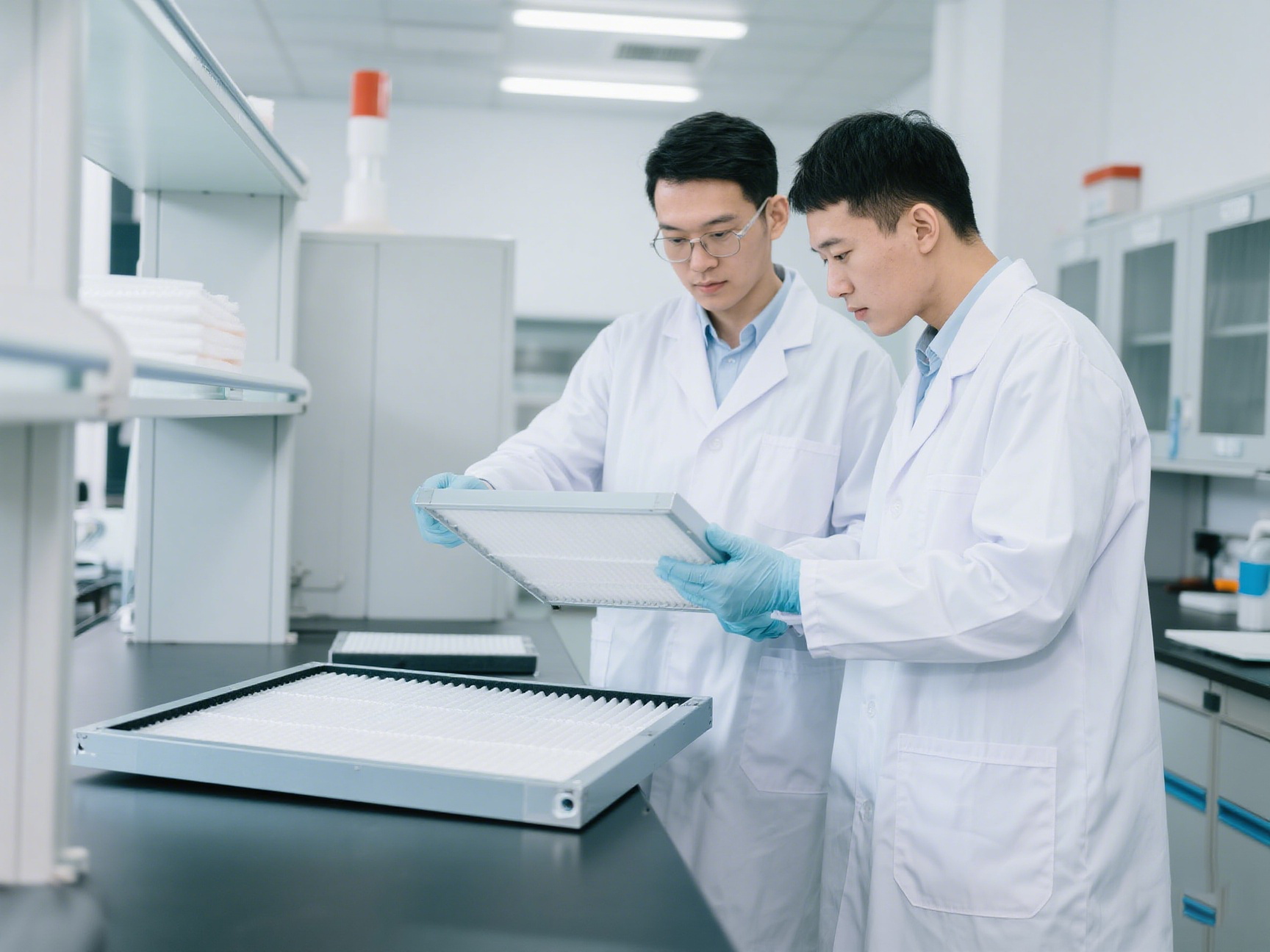

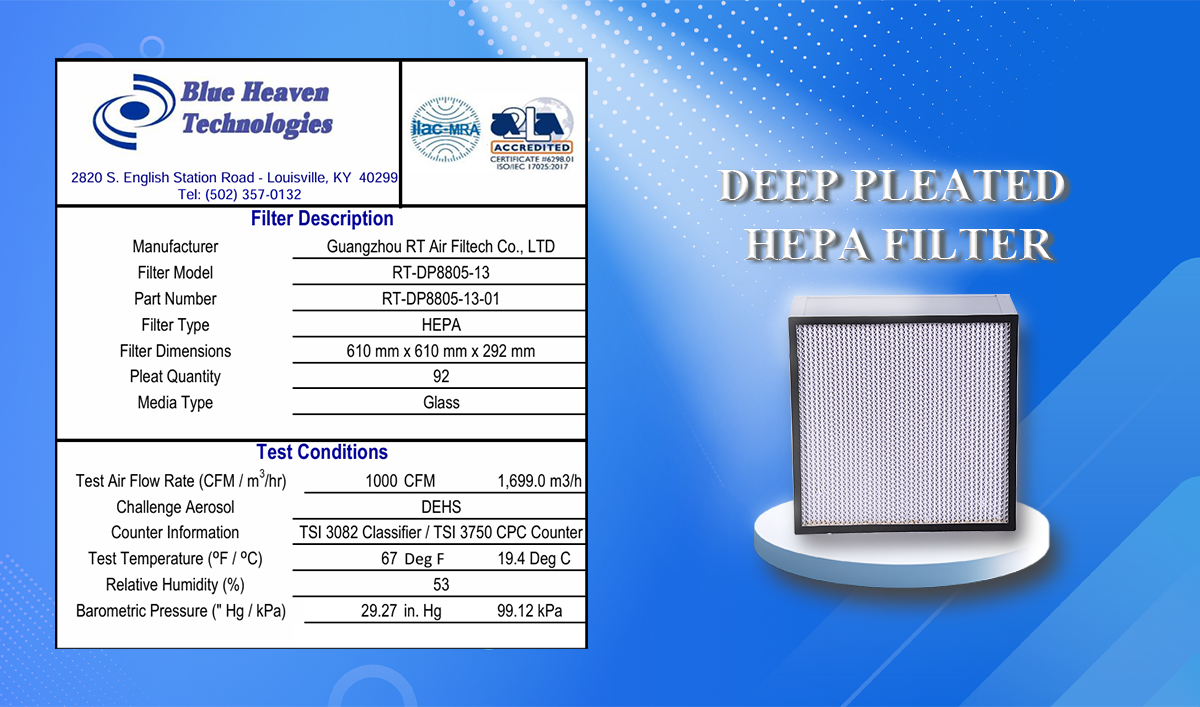

If you are looking for a new filter for your paint booth, be sure to consult with a relevant professional filter manufacturer. Guangzhou RT Air Filtech Co., Ltd. is a production-oriented enterprise integrating R&D, production, sales and service. It is committed to offer related ranges of air filters for industries such as electronics factory, semiconductor, liquid crystal display, bio-pharmaceutical, food, petrochemical industry, clean room, hospital,rail transit, spray booth, commercial and residential construction.

Our business has spread to more than 50 countries and regions around the world and is highly appreciated and recognized by customers at home and abroad.