Nowadays, global climate change has become the focus of more and more people's attention, and it is a brand new initiative for us to implement low-carbon economy through technological innovation and development. The low-carbon economy, environmental protection economy, sustainable development, etc. that we advocate now cannot be separated from the protection of environmental health, and the development of activated carbon filter is inseparable.

Activated carbon filters can not only bring economic benefits, but can also form a strong new growth point for the international economy.

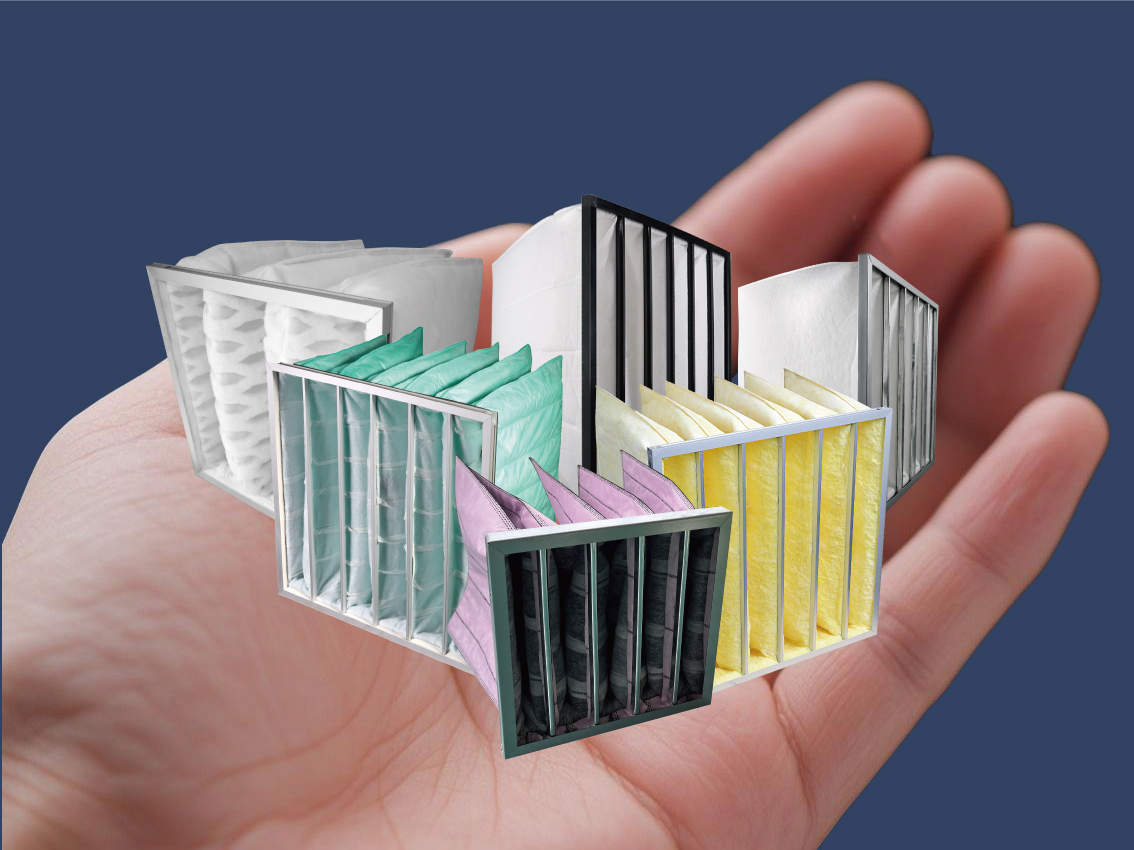

|

1、What is activated carbon?

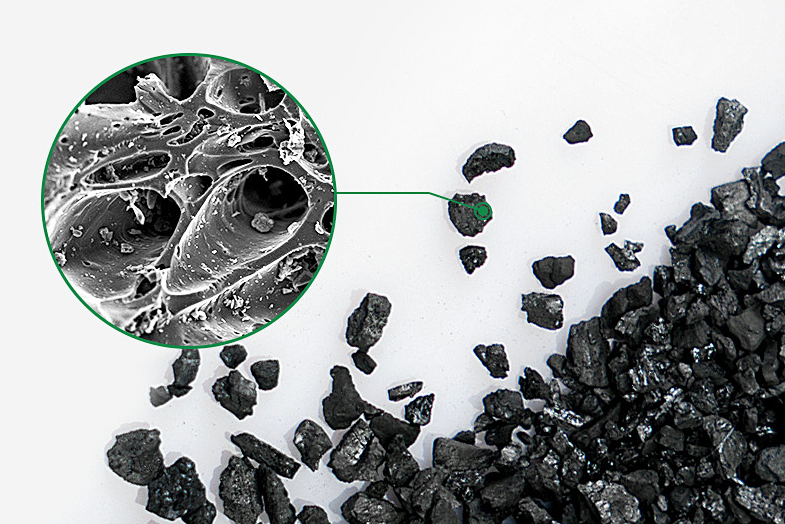

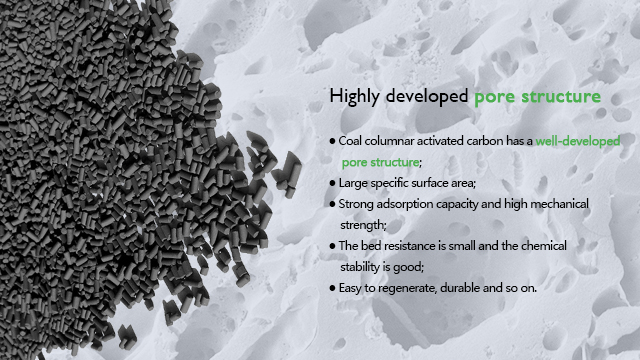

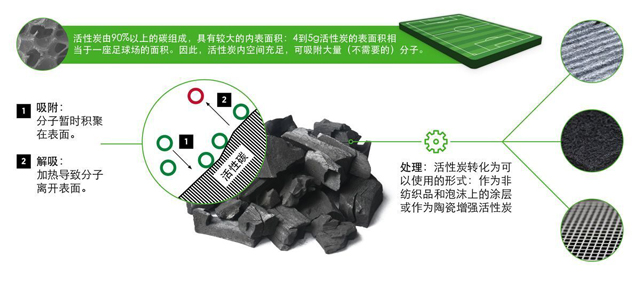

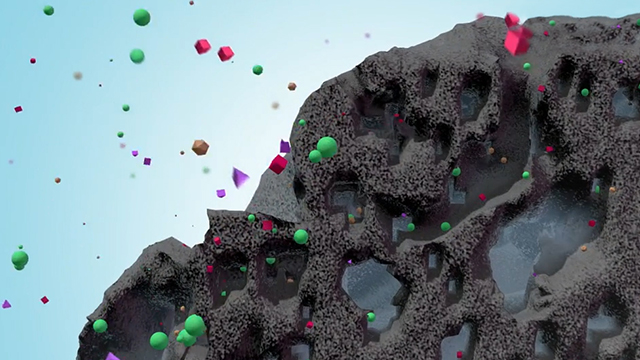

Activated carbon is carbon that has been treated with CO2 or superheated steam at very high temperatures. This creates a matrix of tiny pores in the carbon, increasing its surface area and creating more places for molecules to be trapped, which is what makes carbon an effective filter medium. Activated carbon filters are also often chemically treated to improve their ability to trap specific contaminants.

|

Activated carbon filters are also known as molecular filters (sometimes called chemical filters or gas phase filters). They usually use a technique called "adsorption". In short, molecules are stuck to a material with a very high surface area.

The structure of activated carbon has millions of micropores, and a pound of carbon has a surface area of over 6 million square feet, which allows the carbon to maintain its gas capture efficiency over a long period of time, up to 4 years in some HVAC applications.

2、How activated carbon air filters capture pollutants

Activated carbon air filters remove pollutants from the air through a process of adsorption, which is different from absorption.

The key to the difference is that in the adsorption process, the contaminant sticks to the outside of the carbon; while in the absorption process, the contaminant is absorbed inside the structure itself, just like a sponge absorbs water; the water does not chemically bond with the sponge, it just fills the space inside it.

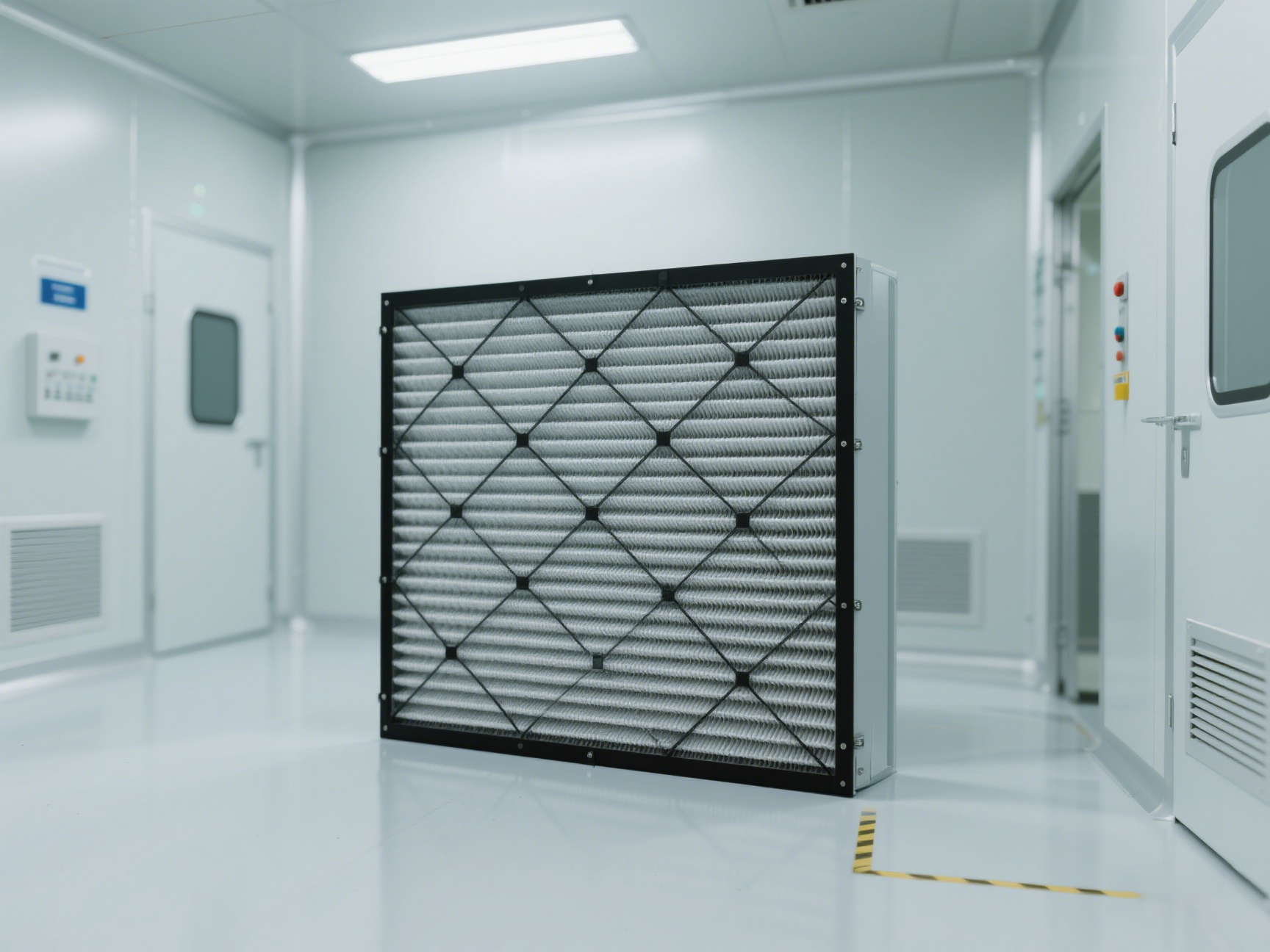

|

Carbon is a lattice of interconnected carbon atoms. When a molecule of some gaseous substance passes through the carbon, it can adhere to the surface of the carbon bed, provided that it is activated to generate adsorbable sites.

During adsorption, gaseous contaminants gradually fill up the adsorption sites of the activated carbon. Once the carbon bed is saturated, the filter can no longer capture the contaminants.

Also, chemicals with greater affinity for the adsorption site can replace chemicals with less affinity, and the affinity of a given chemical for the adsorbent is highly dependent on environmental conditions, such as temperature and relative humidity.

Therefore, as conditions change, different chemicals may be released from the filter. When an activated carbon air filter becomes saturated, you may notice that it gives off a strange odor. This is a strong indicator that it is time to replace your carbon filter.

3、Use of activated carbon air filter

Activated carbon is versatile in that it controls most of the molecules that pollute the air, about 150 million chemicals. It is also used to eliminate odors in wastewater treatment plants and other manufacturing processes.

1、Separation and removal of harmful gases in the air. Activated carbon air filter can effectively filter VOC in the air. it can also remove harmful gases in the air: such as toluene, ketones, alcohols, tetrahydrofuran, methylene chloride, trichloromethane, trichloroethylene, perchloroethylene, carbon disulfide, formyl, gasoline, fluorinated hydrocarbons, etc. These are gaseous substances that most other mechanical filters (such as HEPA filters) cannot filter.

Some of the gases commonly found in cigarette smoke, dried paint or cleaning products can also be removed from the air by carbon filters.

2、Filtering odor. Mechanical air purifiers that can only filter particles simply cannot remove unpleasant odors. Therefore, people often use activated carbon air filters to remove odors. Of course, there are also odors that cannot be removed by activated carbon filters.

4、How to use activated carbon air filter effectively

Activated carbon air filters are an important part of an air purification system in a home or industrial production and must be used properly.

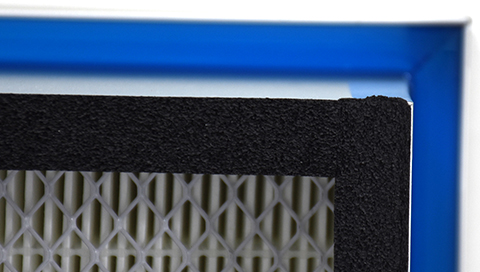

1. Make sure the filter system uses enough carbon. A rough guideline is that a good activated carbon air filter uses at least 5 pounds of carbon. Of course, not all carbon is created equal, and some may have more binding sites than others.

Therefore, the more effective the filter is with sufficient carbon content, the more effective the filtration will be, because there are sufficient adsorption sites to adhere to. Conversely, the effect is less effective.

2. The "residence time" of the airflow is critical. In order to remove as many contaminants as possible from the air, the air needs to spend as much time as possible passing through the activated carbon air filter. In the air filtration industry, this is called "residence time".

A filter with a large amount of carbon of sufficient thickness and long residence time will be more effective than a filter with a thin carbon layer.

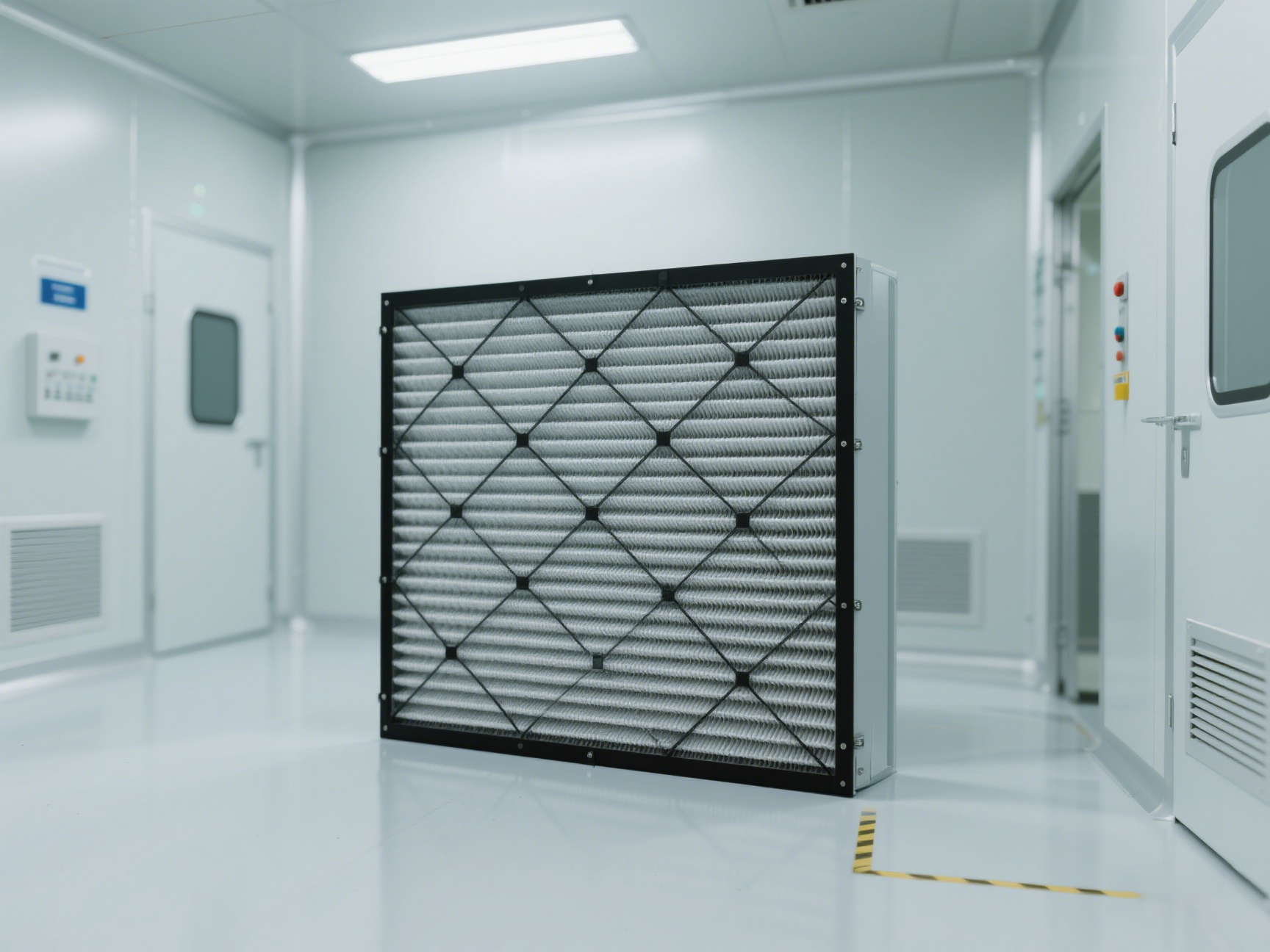

|

3、Replacement of carbon filter. Once the carbon is saturated, the carbon filter loses its effectiveness and must be replaced with a new carbon filter in time.

The problem is that there is no perfect way to know when carbon is saturated. Sometimes you'll notice the smell; sometimes you won't. You can follow the manufacturer's guidelines and change it regularly.

The degree of carbon saturation depends on the amount of carbon used and the amount of contaminants to which it is exposed.

Note that according to the EPA, carbon monoxide cannot be easily removed by gas phase filters, so other important steps (such as installing a carbon monoxide detector) must be used to prevent exposure

5、Should you use an activated carbon air filter?

If it is during a home renovation, or if you are concerned about household products, building materials, etc. (such as formaldehyde) releasing VOCs in your home, using an activated carbon filter to remove odors in the short term is an acceptable option in these cases. However, in the long run, the cost is higher.

If it is applied to the exhaust gas filtration before the exhaust gas emission of the painting workshop or electronic plant or various ventilation systems such as fresh air purification and exhaust gas emission and other industrial filtration.

Separates and removes odors (bad smells) and harmful gases from the air and purifies the air in the work environment.

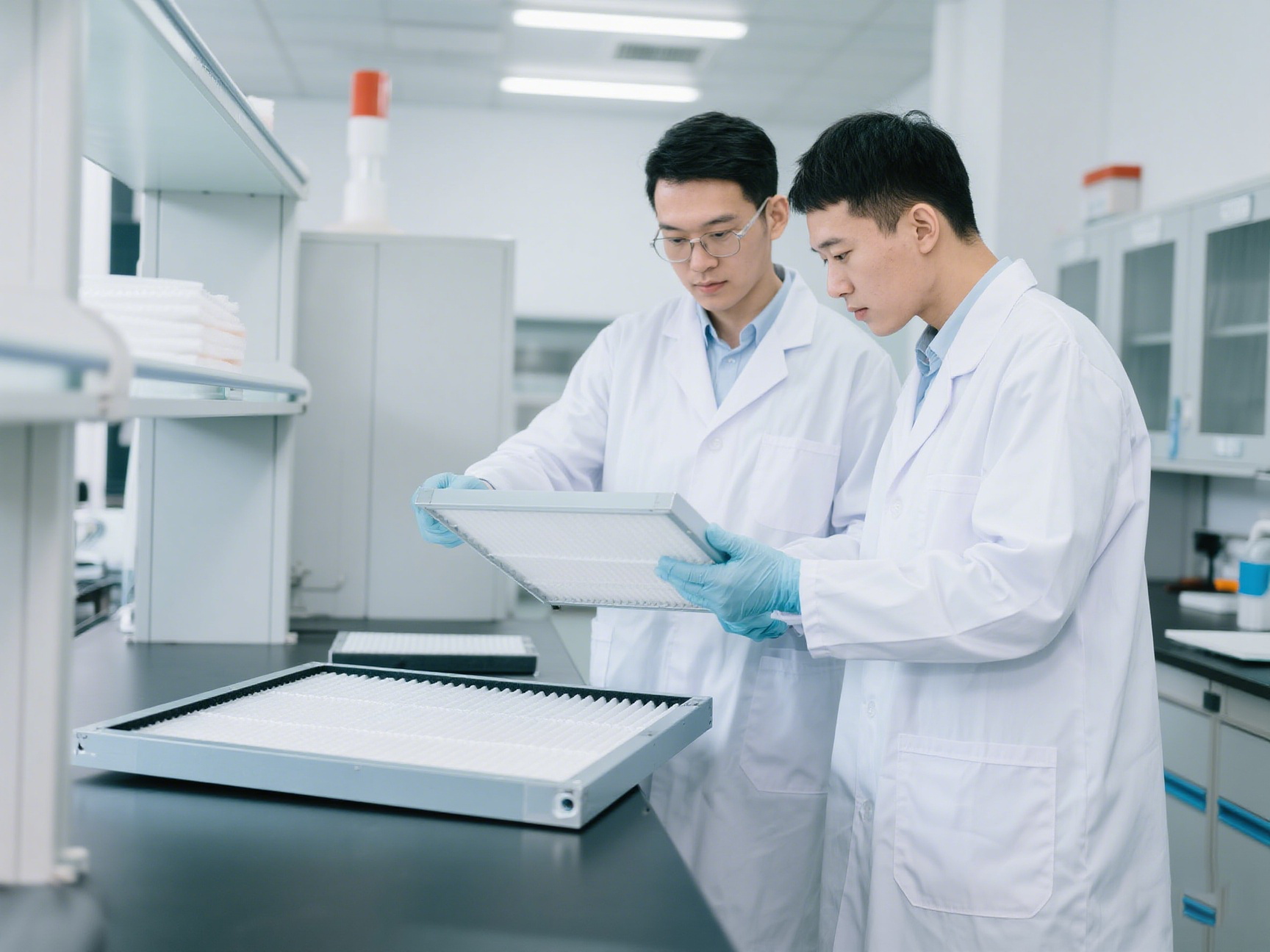

|

In this case, an activated carbon filter is a necessary investment.

Dust, fumes, chemicals, odors, welding gases or other air impurities from industrial production processes, various functional operations and industrial facilities generated by mechanical production and handling are mixed into indoor air to adversely affect the lives of employees, leading to low work efficiency and, in the worst case, even to employee health problems.

Effective air purification of supply and exhaust air through activated carbon filters is a decisive factor in preventing employee health problems, increasing efficiency and reducing costs in many production processes.