Our company has a vibrant sales team composed of highly educated and high-quality talents, with many years of industry-related experience in technology, products, operations, and sales management.

Under the company's own sales process, a scientific management system has been formed. RT team members are young and energetic, efficient, innovative and brave to meet challenges. They all have a good sense of social responsibility and are willing to contribute to the improvement of global air quality.

We firmly believe in the importance of user-centered, and strive to achieve user-centered innovation and solutions to help customers achieve long-term development.

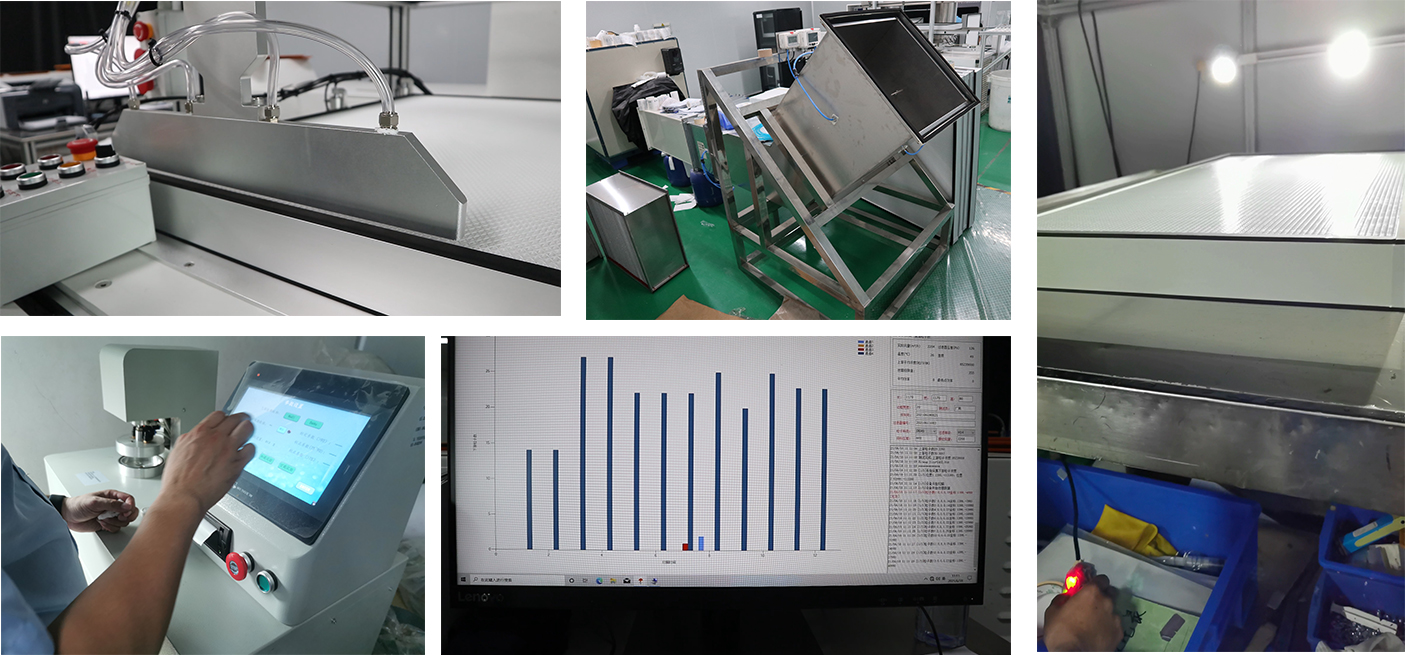

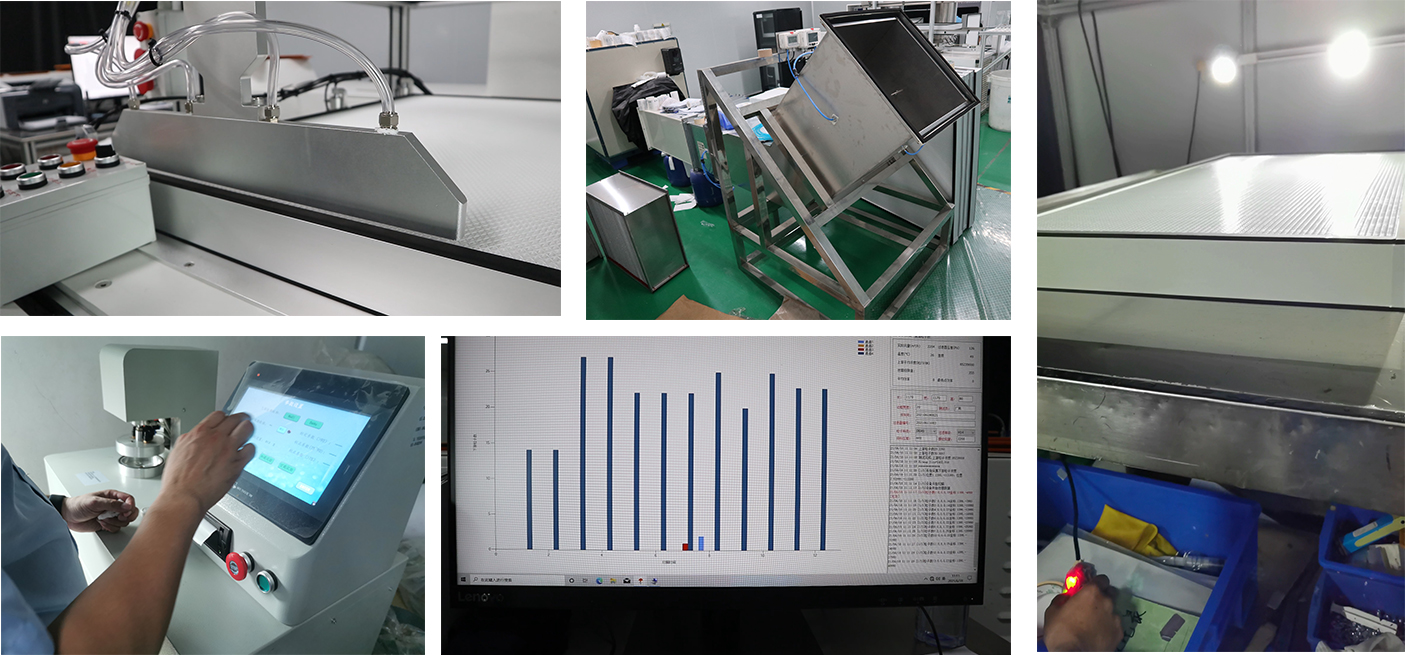

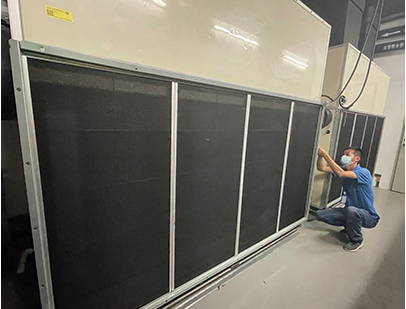

In order to ensure the quality of products, Guangzhou Rongteng has strict quality inspection and control standards for production, processing and manufacturing.

1. Strictly control incoming materials to ensure product quality from raw materials. Strictly control the purchased raw materials. This step will be divided into two steps for quality control and verification. The first step is for the warehouse management staff to check the incoming standard raw materials, and the qualified raw materials are stored in the warehouse. Non-standard raw materials are tested at the processing site. The second step is for the personnel of the quality inspection department to recheck and inspect the incoming products before processing and production. At the same time, the processing personnel in each process will conduct pre-processing inspections on the raw materials they use. Only qualified raw materials tested by processing personnel can be used in product processing and production.

2. The self-inspection process of the production process. There are strict inspection procedures for each process in production. Production personnel must conduct self-inspection on each link of production, and record the results of self-inspection. After each process is completed, the production staff will conduct a comprehensive self-inspection of the finished product that is about to enter the quality control and inspection process. After the self-inspection is correct, the finished product will enter the next link: quality control and inspection process.

3. Confirmation of the consistency between the ordered product specifications and the finished product. In order to ensure the consistency of the produced product and the order, after the finished product is processed, the staff in charge of the quality supervision department will conduct a review of each batch of ordered products and the finished products Compare to ensure that the products we produce meet customer requirements. After confirming the specifications, the finished product will enter the final running inspection process.

4. We have a special technical testing process to test every product before leaving the factory to ensure that our products meet the relevant domestic and foreign standards. Therefore, we can ensure that the products listed in the tender fully meet the requirements of our product specifications Commitment. Provide quality products.